Development of high performance ductile hybrid composites

Dr. Gergely Czél

Dr. László Mészáros

Dr. Kolos Molnár

Prof. Dr. h.c. mult. József Karger-Kocsis

Dr. Dániel Gere

Norbert András Forintos

Dr. Gergely Hegedűs

Project summary

One of the biggest challenges for the 21st century’s transportation sector in line with the strategic aims of the EU is to improve fuel economy and reduce emissions, which may be done by reduction of the gross weight of vehicles. The development of the next generation of economic and environmentally friendly vehicles requires high strength and low weight components. So-called composite materials consisting of fibres and plastic resins offer high strength but usually fail in a catastrophic manner without sufficient warning. This unsafe failure character renders them unsuitable for several applications where loads are unpredictable and sudden failure cannot be tolerated. Our research programme aims at developing a new generation of composites featuring safe, gradual failure, with significant margin between a detectable warning and final failure. Our approach is to mix (hybridise) fibre types and design the layered architecture of our new materials to mimic the safe ductile failure of metals. Our previous success in developing hybrid composites showing ductility in one direction encourages us to develop more advanced types which can be loaded in any directions. Our new materials could potentially offer a notable increase in the scope of composite applications including transportation and construction sectors. A significant shift in the conservative design limits leading to lower component weights and therefore operational cost savings could potentially take place as well due to safer failure character of the new ductile composites.

Project results

Project-related publications

- Czél G. , Bugár-Mészáros M., Wisnom M. R.: Combined effect of moisture and test temperature on the pseudo-ductility of thin-ply carbon/epoxy-glass/epoxy hybrid composites. Composites Part A: Applied Science and Manufacturing, 165, 107353/1-107353/11 (2023) 10.1016/j.compositesa.2022.107353 IF=8.1 Q1

- Petrény R., Mészáros L.: Moisture dependent tensile and creep behaviour of multi-wall carbon nanotube and carbon fibre reinforced, injection moulded polyamide 6 matrix multi-scale composites. Journal of Materials Research and Technology, 16, 689-699 (2022) 10.1016/j.jmrt.2021.12.030 IF=6.4 D1

- Vermes B., Czigány T.: Non-conventional deformations: Materials and actuation. Materials, 13, 1383/1-1383/26 (2020) 10.3390/ma13061383 IF=3.623 Q1

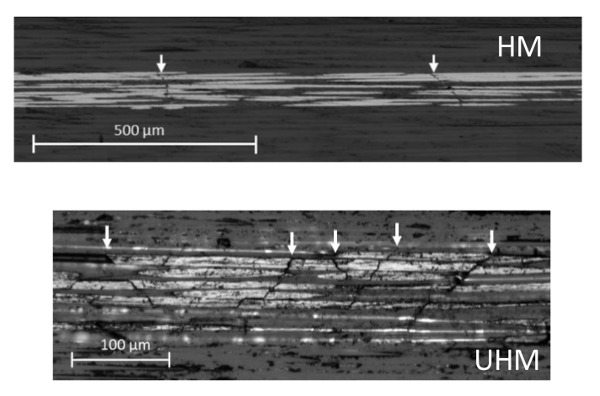

- Hegedűs G., Sarkadi T., Czigány T.: Self-sensing composite: Reinforcing fiberglass bundle for damage detection. Composites Part A: Applied Science and Manufacturing, 131, 105804/1-105804/7 (2020) 10.1016/j.compositesa.2020.105804 IF=7.664 D1

- Hegedűs G., Czigány T.: State monitoring of polymer composites with glass optical fibre and with equipment used in telecommunication. Acta Materialia Transylvanica, 3, 1-9 (2020) 10.33924/amt-2020-01-01

- Forintos N., Czigány T.: Reinforcing carbon fibers as sensors: The effect of temperature and humidity. Composites Part A: Applied Science and Manufacturing, 131, 105819/1-105819/5 (2020) 10.1016/j.compositesa.2020.105819 IF=7.664 D1

- Mészáros L., Kara Y., Fekete T., Molnár K.: Development of self-reinforced low-density polyethylene using γ-irradiation cross-linked polyethylene fibres. Radiation Physics and Chemistry, 170, 108655/1-108655/6 (2020) 10.1016/j.radphyschem.2019.108655 IF=2.858 D1

- He H. J., Kara Y., Molnar K.: In Situ Viscosity-Controlled Electrospinning with a Low Threshold Voltage. Macromolecular Materials and Engineering, 304, 1900349/1-1900349/ (2019) 10.1002/mame.201900349 IF=3.853 Q1

- Hegedűs G., Sarkadi T., Czigány T.: Self-sensing polymer composite: white-light-illuminated reinforcing fibreglass bundle for deformation monitoring. Sensors, 19, 1745/1-1745/8 (2019) 10.3390/s19071745 IF=3.275 Q1

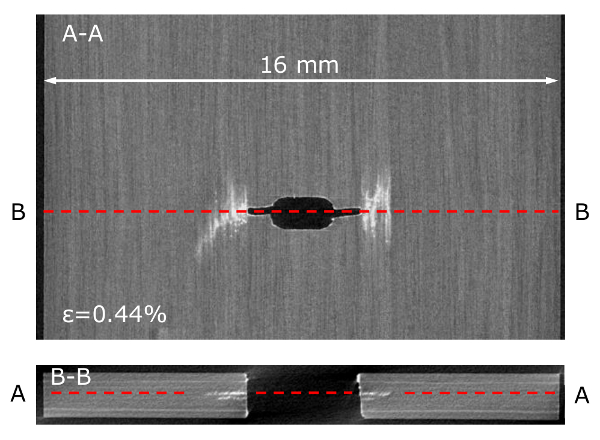

- Rev T., Jalalvand M., Fuller J., Wisnom M. R., Czél G.: A simple and robust approach for visual overload indication - UD thin-ply hybrid composite sensors . Composites Part A: Applied Science and Manufacturing, 121, 376-385 (2019) 10.1016/j.compositesa.2019.03.005 IF=6.444 D1

- Vas L. M., Kocsis Z., Czigány T., Tamás P., Romhány G.: Novel evaluation method of acoustic emission data based on statistical fiber bundle cells. Journal of Composite Materials, 53, 2429-2446 (2019) 10.1177/0021998319826666 IF=1.972 Q3

- Toldy A., Szebényi G., Molnár K., Tóth L. F., Magyar B., Hliva V., Czigány T., Szolnoki B.: The effect of multilevel carbon reinforcements on the fire performance, conductivity, and mechanical properties of epoxy composites. Polymers, 11(2), 303/1-303/13 (2019) 10.3390/polym11020303 IF=3.426 Q1

- Hegedűs G., Sarkadi T., Czigány T.: Multifunctional composite: Reinforcing fibreglass bundle for deformation self-sensing. Composites Science and Technology, 180, 78-85 (2019) 10.1016/j.compscitech.2019.05.018 IF=7.094 D1

- He H., Kara Y., Molnár K.: Effect of needle characteristic on fibrous PEO produced by electrospinning. Resolution and Discovery, 4, 7-11 (2019) 10.1556/2051.2018.00063

- Csallány E. K., Czél G.: Rendezett nem folytonos szálakkal erősített, nagy teljesítményű polimer kompozitok mechanikai tulajdonságai nyomó terhelés esetén. Polimerek, 5, 388-392 (2019)

- Tamás-Bényei P., Bitay E., Kishi H., Matsuda S., Czigány T.: Toughening of Epoxy Resin: The Effect of Water Jet Milling on Worn Tire Rubber Particles. Polymers, 11, 529/1-529/11 (2019) 10.3390/polym11030529 IF=3.426 Q1

- Vermes B., Czigány T.: Layup optimization and ways to improve the manufacturability of coupled composites. in 'International Conference on Composite Materials (ICCM22) Melbourne, Australia. 2019.08.11-2019.08.16,7 (2019)

- Molnár K.: Electrospinning setup analogous to a cone-plate rheometer. Materials Today Communications, 20, UNSP 10058/1-UNSP 10058/ (2019) 10.1016/j.mtcomm.2019.100589 IF=2.678 Q2

- Virág Á. D., Vas L. M., Bakonyi P., Halász M.: Analysing of the Yarn Pull-out Process for the Characterization of Reinforcing Woven Fabrics. Fibers and Polymers, 20, 1975-1982 (2019) 10.1007/s12221-019-8978-9 IF=1.797 Q1

- Hegedűs G., Czigány T.: Sérülés helyének megállapítása kompozit szerkezetekben az üveg erősítőanyag felhasználásával. in 'XXVII. Nemzetközi Gépészeti Konferencia OGÉT 2019 Nagyvárad. 2019.04.25-2019.04.28.,189-192 (2019)

- Forintos N., Czigány T.: Multifunctional application of carbon fiber reinforced polymer composites: electrical properties of the reinforcing carbon fibers – a short review. Composites Part B: Engineering, 162, 331-343 (2019) 10.1016/j.compositesb.2018.10.098 IF=7.635 D1

- Suwarta P., Fotouhi M., Czel G., Longana M., Wisnom M. R.: Fatigue behaviour of pseudo-ductile unidirectional thin-ply carbon/epoxy-glass/epoxy hybrid composites. Composite Structures, 224, UNSP 11099/1-UNSP 11099/ (2019) 10.1016/j.compstruct.2019.110996 IF=5.138 D1

- Rév T., Czél G., Wisnom M. R.: A Novel Test Method to Induce Bi-axial Stress States in Thin-ply Carbon Composites Under Combined Longitudinal Tension and Transverse Compression. in 'American Society for Composites—Thirty-Third Technical Conference on Composite Materials Seattle, USA. 2018.09.24. - 2018.09.,9 (2018)

- Hegedűs G., Czigány T.: Analysis of the applicability of optical fibers as sensors for the structural health monitoring of polymer composites: the relationship between attenuation and the deformation of the fiber. Sensors and Actuators A: Physical, 272, 206-211 (2018) 10.1016/j.sna.2018.01.039 IF=2.739 Q2

- Vermes B., Czigány T.: Kompozitok alakváltásának lehetőségei. Gép, 69, 51-54 (2018)

- Suwarta P., Czél G., Fotouhi M., Rycerz J., Wisnom M. R.: Pseudo-ductility of Unidirectional Thin Ply Hybrid Composites in Longitudinal Compression. in 'American Society for Composites—Thirty-Third Technical Conference on Composite Materials Seattle, USA. 2018.09.24. - 2018.09.,10 (2018)

- Wisnom M. R., Czél G., Fotouhi M., Fuller J., Jalalvand M., Rev T., Wu X.: Reduced tensile notch-sensitivity in pseudo-ductile thin-ply composites. in '18th European Conference on Composite materials, ECCM18 Athens, Greece. 2018.06.24-2018.06.28.,1-7 (2018)

- Petrény R., Mészáros L.: Poliamid 6 mátrixú hibridkompozitok kúszási jellemzői. Polimerek, 4, 192-196 (2018)

- Fotouhi M., Suwarta P., Jalalvand M., Czel G., Wisnom M. R.: Acoustic Emission Monitoring of Thin Ply Hybrid Composites under Repeated Quasi-Static Tensile Loading. FME Transactions, 46, 238-244 (2018) 10.5937/fmet1802238F

- Czél G., Bugár-Mészáros M., Wisnom M. R.: The effect of test temperature on the pseudo-ductility of thin-ply hybrid composites. in '18th European Conference on Composite materials, ECCM18 Athens, Greece. 2018.06.24-2018.06.28.,1-8 (2018)

- Hegedűs G., Czigány T.: Polimer kompozit termékek komplexitását kihasználó üvegszálas érzékelő csatlakozójának fejlesztése. in 'OGÉT 2018: XXVI. Nemzetközi Gépészeti Konferencia Marosvásárhely, Románia. 2018.04.26-2018.04.29.,179-182 (2018)

- Hegedűs G., Czigány T.: Developing a glass fibre sensor for polymer technology applications. IOP Conference Series: Materials Science and Engineering, 426, 012015/1-012015/1-4 (2018) 10.1088/1757-899X/426/1/012015

- Haijun H., Cheng-Kun L., Molnár K.: A Novel Needleless Electrospinning System Using a Moving Conventional Yarn as the Spinneret. Fibers and Polymers, 19, 1472-1478 (2018) 10.1007/s12221-018-8183-2 IF=1.439 Q1

- Czél G., Rev T., Jalalvand M., Fotouhi M., Longana M. L., Nixon-Pearson O. J., Wisnom M. R.: Pseudo-ductility and reduced notch sensitivity in multi-directional all-carbon/epoxy thin-ply hybrid composites. Composites Part A: Applied Science and Manufacturing, 104, 151-164 (2018) 10.1016/j.compositesa.2017.10.028 IF=6.282 D1

- Szebényi G., Magyar B., Iványicki T.: Comparison of static and fatigue interlaminar testing methods for continuous fiber reinforced polymer composites. Polymer Testing, 63, 307-313 (2017) 10.1016/j.polymertesting.2017.08.033 IF=2.247 Q2

- Molnár K., Czigány T.: High throughput nanofiber production by rotation-aided needleless electrospinning. in 'ICCM21 Xi'an, Kína. 2017.08.20-2017.08.25.,7 (2017)

- Czél G., Jalalvand M., Wisnom M. R., Czigány T.: Design and characterisation of high performance, pseudo-ductile all-carbon/epoxy unidirectional hybrid composites. Composites Part B: Engineering, 111, 348-356 (2017) 10.1016/j.compositesb.2016.11.049 IF=4.92 D1

- Vas L. M., Kling S., Czigány T., Czél G.: New method for determining the bending modulus of solid and hollow fibers from deflection tests. Textile Research Journal, 87, 542-551 (2017) 10.1177/0040517516632476 IF=1.54 Q1

- Péter B., Hegedűs G., Czigány T.: T-RTM eljárással gyártott alkatrészek gyártási folyamatának kihívásai, különös tekintettel az erősítőanyagok kezelésére. Gép, 68, 37-42 (2017)

- Szebényi G., Czigány T., Magyar B., Karger-Kocsis J.: 3D printing-assisted interphase engineering of polymer composites: Concept and feasibility. Express Polymer Letters, 11, 525-530 (2017) 10.3144/expresspolymlett.2017.50 IF=3.064 Q1

- Szebényi G., Tóth L. F., Karger-Kocsis J.: Effect of an Ionic Liquid on the Flexural and Fracture Mechanical Properties of EP/MWCNT Nanocomposites. Materials Science Forum, 885, 19-24 (2017) 10.4028/www.scientific.net/MSF.885.19

- Forintos N., Czigány T.: Üvegszál erősítésű kompozitok deformációjának mérése szénszálak segítségével. in 'OGÉT 2017: XXV. Nemzetközi Gépészeti Konferencia Kolozsvár, Románia. 2017.04.27-2017.04.30.,147-150 (2017)

- Hegedűs G., Czigány T.: Optikai szálak alkalmazása polimer anyagvizsgálatokhoz. in 'OGÉT 2017: XXV. Nemzetközi Gépészeti Konferencia Kolozsvár, Románia. 2017.04.27-2017.04.30.,175-178 (2017)

- Romhány G., Czigány T., Karger-Kocsis J.: Failure Assessment and Evaluation of Damage Development and Crack Growth in Polymer Composites Via Localization of Acoustic Emission Events: A Review. Polymer Reviews, 57, 397-439 (2017) 10.1080/15583724.2017.1309663 IF=6.69 D1

- Czigány T., Forintos N., Hegedűs G.: Health monitoring of high-performance polymer composites with multifunctional fibers. in 'ICCM21 Xi'an, Kína. 2017.08.20-2017.08.25.,8 (2017)

- Vermes B., Czigány T.: Development of microcapsules. Materials Science Forum, 885, 31-35 (2017) 10.4028/www.scientific.net/MSF.885.31

- Hegedűs G., Sarkadi T., Czigány T.: Analysis of the light transmission ability of reinforcing glass fibers used in polymer composites. Materials, 10(6), 637/1-9 (2017) 10.3390/ma10060637 IF=2.467 Q2

- Forintos N, Czigány T: Polimer kompozitok állapotfelügyelete. in 'OGÉT 2016 Déva, Románia. 2016.04.21-2016.04.24.,130-133 (2016)

- Czél G., Jalalvand M., Wisnom M. R.: Hybrid specimens eliminating stress concentrations in tensile and compressive testing of unidirectional composites. Composites Part A: Applied Science and Manufacturing, 91, 436-447 (2016) 10.1016/j.compositesa.2016.07.021 IF=4.075 D1

- Hegedűs G, Czigány T: Kompozit termékek állapotelemzési módszerei. Gép, 67, 98-103 (2016)

- Szebenyi G., Czigany T., Vermes B., Ye X. J., Rong M. Z., Zhang M. Q.: Acoustic emission study of the TDCB test of microcapsules filled self-healing polymer. Polymer Testing, 54, 134-138 (2016) 10.1016/j.polymertesting.2016.07.005 IF=2.464 Q1

- Jalalvand M., Czél G., Fuller J. D., Wisnom M. R., Canal L. P., Gonzalez C. D., LLorca J.: Energy dissipation during delamination in composite materials - An experimental assessment of the cohesive law and the stress-strain field ahead of a crack tip. Composites Science and Technology, 134, 115-124 (2016) 10.1016/j.compscitech.2016.08.001 IF=4.873 D1

- Wisnom M. R., Czél G., Swolfs Y., Jalalvand M., Gorbatikh L., Verpoest I.: Hybrid effects in thin ply carbon/glass unidirectional laminates: Accurate experimental determination and prediction. Composites Part A: Applied Science and Manufacturing, 88, 131-139 (2016) 10.1016/j.compositesa.2016.04.014 IF=4.075 D1

- Forintos N, Czigány T: Kompozitba épített elektromosan vezető érzékelő. Polimerek, 2, 196-199 (2016)

- Czél G., Jalalvand M., Wisnom M. R.: Design and characterisation of advanced pseudo-ductile unidirectional thin-ply carbon/epoxy-glass/epoxy hybrid composites. Composite Structures, 143, 362-370 (2016) 10.1016/j.compstruct.2016.02.010 IF=3.858 Q1