|

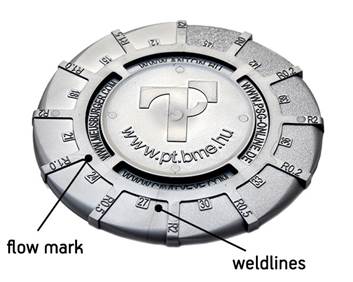

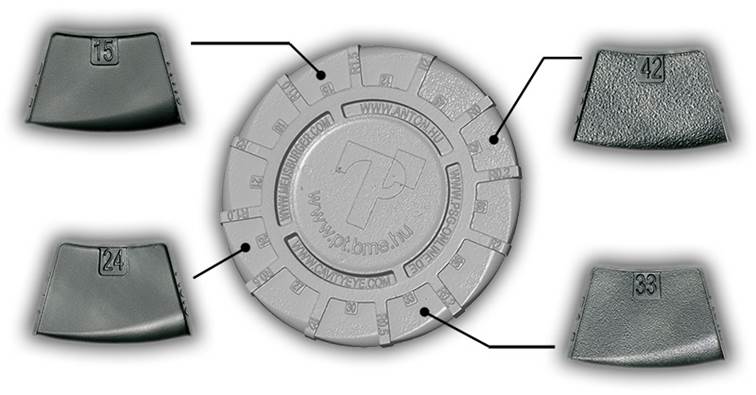

Let us help you with a product that can be a great help in designing injection molded parts, while you can also keep your favorite mug on it. This demonstration part is made from ABS colored with a special silver masterbatch, to highlight all the features, surface finishes, flow marks and surface defects. |

|

|

The product introduces design options that help you design surface roughness, rounding, and other features. It demonstrates wall thickness design errors, which can result in weldlines and flow marks. |

Besides, it can always be on the table with you, since it also functions as a coaster. |

|

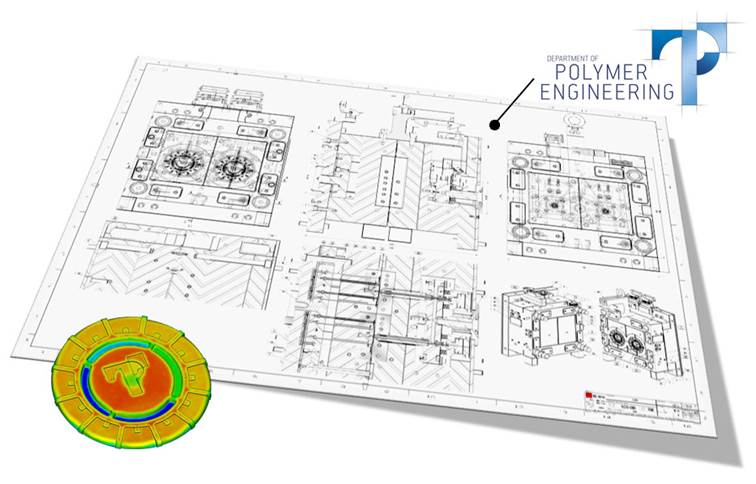

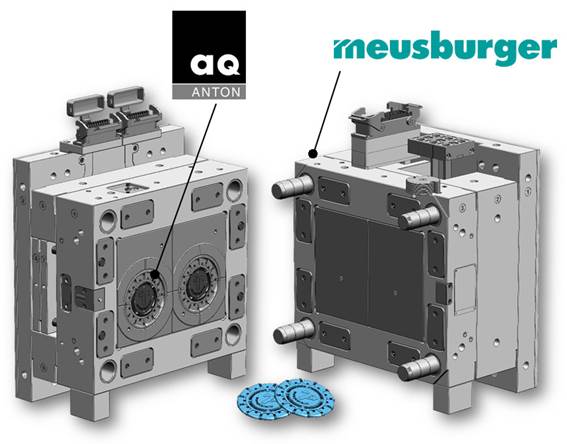

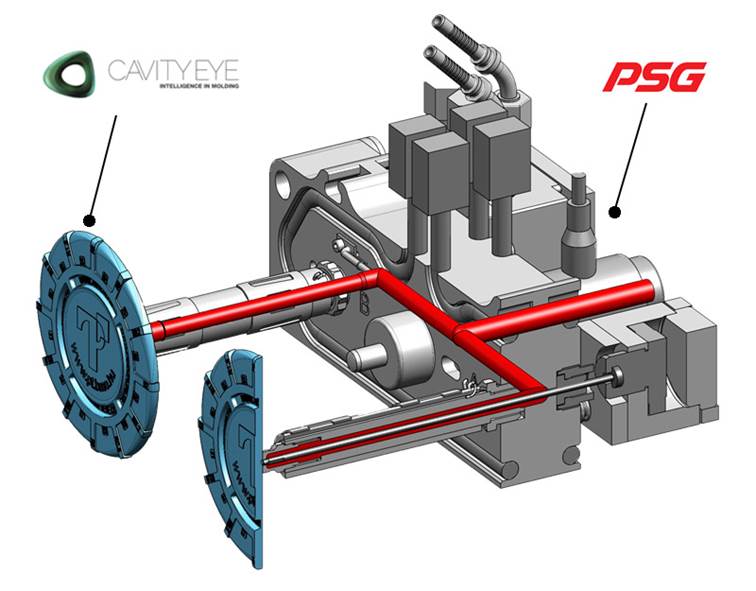

We have designed a hot-runner two-cavity mold, which, in addition to producing the desired design features, helps us demonstrate the possibilities of internal pressure measurement with integrated hot-runner control. |

|

AQ ANTON helped us by making the mold and MEUSBURGER provided the mold plates. |

|

The hot runner and its control were provided by PSG and internal pressure measurement and control was provided by CavityEye. The coasters were injection molded on an Arburg ALLROUNDER 470 A 1000 - 290 L1 provided by ARBURG. |

|

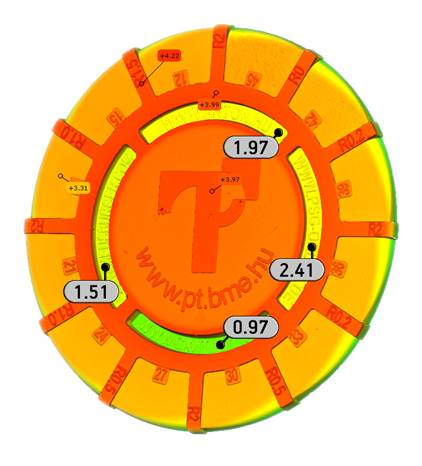

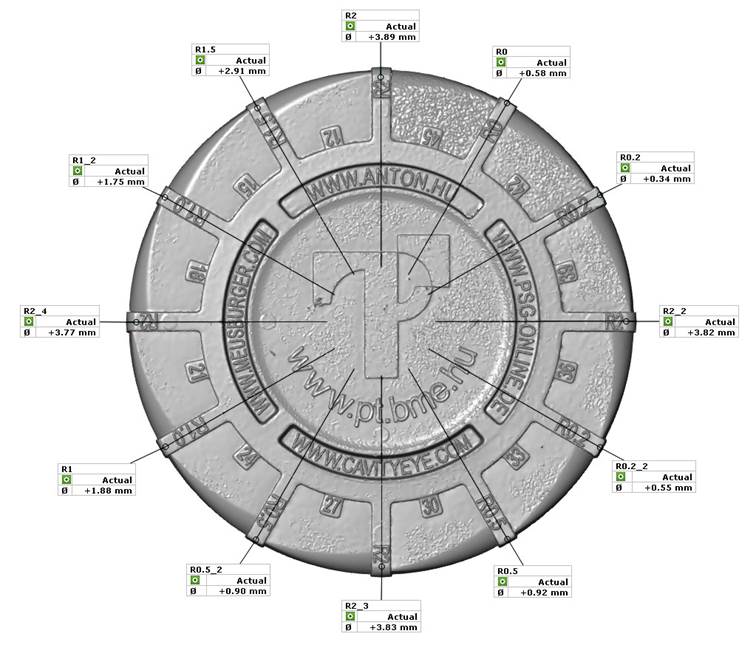

We designed different recesses countersunk onto the part to show possible uneven filling, even if we have a symmetric part. The 3D scan below (by our GOM ATOS Core 5M) shows the thickness variations on the countersunk recesses. |

|

Uneven filling can be seen below. On the left side, the animation from the short shots, while on the right side, the simulation can be seen. |

|

Uneven filling can cause weld lines and flow marks—these can be seen on the part as well. |

|

|

|

|

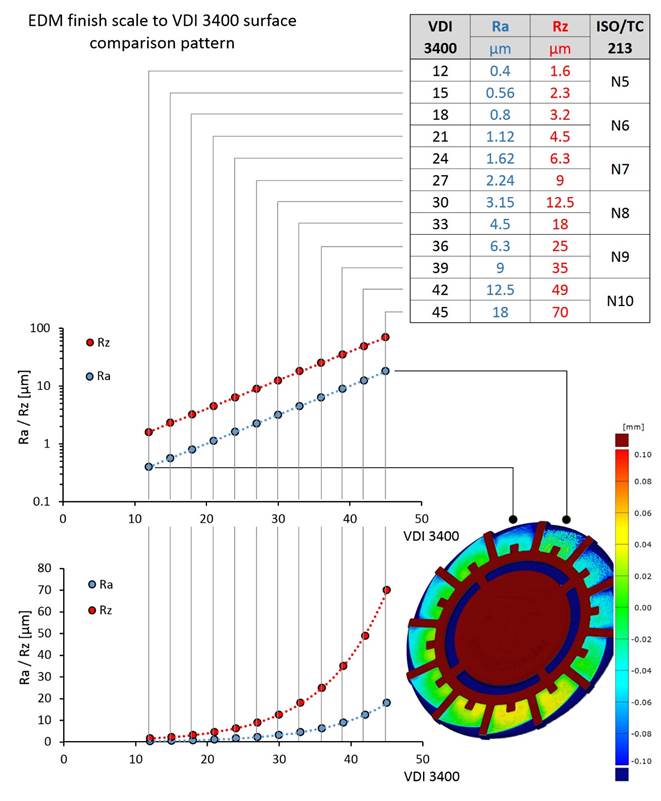

We designed the part with the 12 most common types of VDI 3400 surface finish which can be produced by the EDM method. These surfaces can be seen on the 12 sections of the coasters, each of them numbered according to the VDI 3400 standard. To help the decision, the table below shows the Ra and Rz values for each of those VDI surfaces. |

|

(The surface was measured with a GOM 3D scanner (GOM ATOS Core 5M) and a Keyence microscope (Keyence VHX-5000).) |

|

There are many part design guidelines for injection molded thermoplastic parts, but we would like to give you a part with some good examples for a design with small radii. The part contains 12 ribs with various radii to help designers find the right solutions for their design. One big design question is whether it is possible to design a zero radius (sharp corner). We put a zero and a 0.2 mm radius next to each other to show you the possibilities. Do your customers not believe that it is not good to design a sharp corner where there is no parting plane? Show this product to them. |

|

Nominal and measured values for each radii (note that the measured values are diameters). |

©2019 BME-PT