Production of polymer products by a short cycle time, automatized production technology for automotive applications, with exceptional focus on the complexity and recyclability of the composite parts

Project ID:

NVKP_16-1-2016-0046

Supported by:

Hungarian National Research, Development and Innovation Office (NKFIH)

Term:

1 December 2016 - 31 May 2020

Supervisor (BME):

Prof. Dr. Tibor Czigány

Dr. Gábor Szebényi

Dr. Gábor Szebényi

Participant researchers (BME):

Dr. Péter Bakonyi

Dr. Tamás Bárány

Róbert Boros

Dr. Gergely Czél

Prof. Dr. Tibor Czigány

Dr. Gergely Hegedűs

Prof. Dr. h.c. mult. József Karger-Kocsis

Dr. Zoltán Kiss

Dr. Bálint Morlin

Dr. Kornél Pölöskei

Dr. Péter Tamás-Bényei

Tamás Temesi

Prof. Dr. Andrea Toldy

Dr. András Suplicz

Dr. Ferenc Szabó

Dr. István Zoltán Halász-Kutasi

István Hambalgó

Viktor Hliva

Tamás Temesi

Dr. Zoltán Tamás Mezey

Prof. Dr. Tibor Czvikovszky

Prof. Dr. László Mihály Vas

Dr. Brúnó György Vermes

Dr. Tatyana Ageyeva

Ilya Sibikin

Dr. Tamás Bárány

Róbert Boros

Dr. Gergely Czél

Prof. Dr. Tibor Czigány

Dr. Gergely Hegedűs

Prof. Dr. h.c. mult. József Karger-Kocsis

Dr. Zoltán Kiss

Dr. Bálint Morlin

Dr. Kornél Pölöskei

Dr. Péter Tamás-Bényei

Tamás Temesi

Prof. Dr. Andrea Toldy

Dr. András Suplicz

Dr. Ferenc Szabó

Dr. István Zoltán Halász-Kutasi

István Hambalgó

Viktor Hliva

Tamás Temesi

Dr. Zoltán Tamás Mezey

Prof. Dr. Tibor Czvikovszky

Prof. Dr. László Mihály Vas

Dr. Brúnó György Vermes

Dr. Tatyana Ageyeva

Ilya Sibikin

Consortium partners (BME):

HD Composite Zrt., Evopro Systems Engineering Kft., Econ Engineering Mérnöki, Szolgáltató Kft., MTA TTK

Project summary

The aims of the project are to develop a T-RTM based polyamid matrix endless fiber reinforced composite production cell for large series production of recyclable parts with good surface quality, the thorough investigation of caprolactame processing, the symulation of processes and material behavior.

Project results

Section 1

1 December 2016 - 31 May 2018

Development of caprolactam processing equipment.

Testing of composite material properties for simulation.

Development of preforming tester. Investigation of drapability of textiles and pefrormance of preform binders.

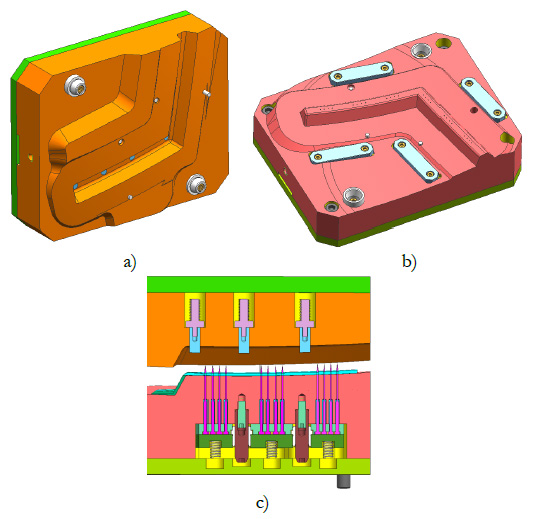

Design of a preforming mould

Section 2

1 June 2018 - 31 May 2019

Design and installation of the T-RTM mould. Design and manufacture of permeability testers with fluid and air medium, permeability testing of different reinforcement materials and preform stacks. Design of overmoulding injection mould. Overmoulding tests on injection moulded and cast polyamide sheets, testing of injection moulding parameters on joint strength. Development of additive compositions for class-A surface.

Test setups of the performed tests

Section 3

1 June 2019 - 31 May 2020

In the third work period the following tasks were carried out at BME:

Literature survey in the field of permeability of reinforcing structures, surface coatings, overmoulding and joining technologies.

Investigation of the effects of additives for use in surface coatings. Casting tests. Creation and characterization of in-mould surface coatings.

Knowledge and technology transfer.

Permeability testing with air and liquid, setting up the correlations.

Development of in-mold coating technology.

Overmoulding, optimization of the contact of the overmoulded parts and the carrier, investigation of the effect of technological parameters.

Development of joining and final machining technologies.

As the final result of the project the first automatized T-RTM production line of Hungary was created. The technology is able to create novel, resistant in mould coatings in the same step as the production of the composite base structure.

The developed T-RTM production line (T-RTM press with the designed mould - left side, T-RTM dosing unit - right side)

Project-related publications

- Semperger O. V., Suplicz A.: The effect of the titanium dioxide nanoparticles on the morphology and degradation of polyamide 6 prepared by anionic ring-opening polymerization. Polymer Engineering and Science, 62, 2079-2088 (2022) 10.1002/pen.25990 IF=3.2 Q2

- Takács L., Szabó F.: Automated determination of the optimal manufacturing direction of polymer composite shell structures. IOP Conference Series: Materials Science and Engineering, 1246, 012026/1-012026/8 (2022) 10.1088/1757-899X/1246/1/012026

- Semperger O. V., Pomlényi P., Suplicz A.: Felület-bevonatolási eljárás T-RTM technológiához. Polimerek, 7, 186-192 (2021)

- Szebényi G., Magyar B., Czigány T.: Achieving pseudo-ductile behavior of carbon fiber reinforced polymer composites via interfacial engineering. Advanced Engineering Materials, 23, 2000822/1-2000822/7 (2021) 10.1002/adem.202000822 IF=4.122 Q2

- Magyar B., Czigány T., Szebényi G.: Metal-alike polymer composites: The effect of inter-layer content on the pseudo-ductile behaviour of carbon fibre/epoxy resin materials. Composites Science and Technology, 215, 109002/1-109002/8 (2021) 10.1016/j.compscitech.2021.109002 IF=9.879 Q1

- Takács L., Szabó F.: An effective method of modeling the deformation behavior of polymer sandwich structures with adhesive joints. Applied Composite Materials, 28, 1959-1978 (2021) 10.1007/s10443-021-09948-1 IF=2.368 Q3

- Forintos N., Sarkadi T., Czigány T.: Electric resistance measurement–based structural health monitoring with multifunctional carbon fibers: Predicting, sensing, and measuring overload. Composites Communications, 28, 100913/1-100913/4 (2021) 10.1016/j.coco.2021.100913 IF=7.685 Q1

- Szebényi G., Magyar B., Czigány T.: Achieving pseudo-ductile behavior of carbon fiber reinforced polymer composites via interfacial engineering. Advanced Engineering Materials, 23, 2000822/1-2000822/7 (2021) 10.1002/adem.202000822 IF=4.122 Q2

- Forintos N., Sarkadi T., Boros Cs. O., Czigány T.: Multifunctional carbon fiber sensors: The effect of anisotropic electrical conductivity. IEEE Sensors Journal, 21, 8960-8968 (2021) 10.1109/JSEN.2021.3053125 IF=4.325 Q1

- Molnár K., Virág Á. D., Halász M.: Shear and yarn pull-out grip for testing flexible sheets by universal load machines. Polymer Testing, 82, 106345/1-106345/11 (2020) 10.1016/j.polymertesting.2020.106345 IF=4.282 Q1

- Semperger O. V., Suplicz A.: The effect of titanium dioxide on the moisture absorption of polyamide 6 prepared by T-RTM. in '12th Hungarian Conference on Materials Science Balatonkenese, Magyarország. 2019.10.13-2019.10.15,8 (2020)

- Kiss Z., Temesi T., Bitay E., Bárány T., Czigány T.: Ultrasonic welding of all-polypropylene composites. Journal of Applied Polymer Science, 137, 48799/1-48799/7 (2020) 10.1002/app.48799 IF=3.125 Q2

- Szebényi G., Hliva V., Magyar B.: Development of interphase engineering techniques for the ductility improvement in CF/EP composites - Comparison of NDT methods for delamination localization. Materials Today: Proceedings, 34, 113-116 (2020) 10.1016/j.matpr.2020.01.403

- Hegedűs G., Sarkadi T., Czigány T.: Self-sensing composite: Reinforcing fiberglass bundle for damage detection. Composites Part A: Applied Science and Manufacturing, 131, 105804/1-105804/7 (2020) 10.1016/j.compositesa.2020.105804 IF=7.664 D1

- Forintos N., Czigány T.: Multifunctional carbon fiber reinforced polymer composite structures: Reinforcing and sensing. in '6th International Conference on Sensors and Electronic Instrumentation Advances Porto, Portugália. 2020.09.23-2020.09.25.,162-166 (2020)

- Vermes B., Czigány T.: Non-conventional deformations: Materials and actuation. Materials, 13, 1383/1-1383/26 (2020) 10.3390/ma13061383 IF=3.623 Q1

- Takács L., Szabó F.: Modeling the deformation behavior of polymer sandwich structures with inhomogeneous core. IOP Conference Series: Materials Science and Engineering, 903, 012024/1-012024/8 (2020) doi:10.1088/1757-899X/903/1/012024

- Vermes B., Czigány T.: Alakváltó kompozitok tervezése és gyártása autoklávval. Polimerek, 6, 895-899 (2020)

- Takács L., Szabó F.: Polimer kompozit szerkezet redőződés szimulációja. Polimerek, 6, 1106-1110 (2020)

- Takács L., Kovács L., Olajos T.: Numerical tool with mean-stress correction for fatigue life estimation of composite plates. Engineering Failure Analysis, 111, 104456/1-104456/12 (2020) 10.1016/j.engfailanal.2020.104456

- Semperger O. V., Suplicz A.: The Effect of the Parameters of T-RTM on the Properties of Polyamide 6 Prepared by in Situ Polymerization. Materials, 13, 4-14 (2020) 10.3390/ma13010004 IF=3.623 Q1

- Szebényi G., Blößl Y., Hegedűs G., Tábi T., Czigány T., Schledjewski R.: Fatigue monitoring of flax fibre reinforced epoxy composites using integrated fibre-optical FBG sensors. Composites Science and Technology, 199, 108317/1-108317/8 (2020) 10.1016/j.compscitech.2020.108317 IF=8.528 D1

- Takács L., Szabó F.: Experimental and numerical failure analysis of adhesive joint of glass fiber reinforced polymer composite. Periodica Polytechnica-Mechanical Engineering, 64, 88-95 (2020) 10.3311/PPme.15106

- Szebényi G., Hliva V., Tamás-Bényei P.: Investigation of delaminated composites by DIC and AE methods. in 'International Conference on Composite Materials (ICCM22) Melbourne, Australia. 2019.08.11-2019.08.16,7 (2019)

- Forintos N., Czigány T.: Multifunctional application of carbon fiber reinforced polymer composites: electrical properties of the reinforcing carbon fibers – a short review. Composites Part B: Engineering, 162, 331-343 (2019) 10.1016/j.compositesb.2018.10.098 IF=7.635 D1

- Hegedűs G., Czigány T.: Sérülés helyének megállapítása kompozit szerkezetekben az üveg erősítőanyag felhasználásával. in 'XXVII. Nemzetközi Gépészeti Konferencia OGÉT 2019 Nagyvárad. 2019.04.25-2019.04.28.,189-192 (2019)

- Takács L., Szabó F.: Vinilészter mátrixú kompozit ragasztott kötésének törésmechanikai jellemzői. Polimerek, 9, 661-665 (2019)

- Magyar B., Szebényi G., Czigány T.: Comparison of different interfacial engineering methods to achieve pseudo-ductile behaviour of carbon fibre reinforced polymer composites. in 'International Conference on Composite Materials (ICCM22) Melbourne, Australia. 2019.08.11-2019.08.16,9 (2019)

- Semperger O. V., Suplicz A.: Titán-dioxid hatása az in-situ polimerizációval előállított poliamid 6 minták tulajdonságaira. Polimerek, 5, 730-733 (2019)

- Hegedűs G., Sarkadi T., Czigány T.: Multifunctional composite: Reinforcing fibreglass bundle for deformation self-sensing. Composites Science and Technology, 180, 78-85 (2019) 10.1016/j.compscitech.2019.05.018 IF=7.094 D1

- Hegedűs G., Sarkadi T., Czigány T.: Self-sensing polymer composite: white-light-illuminated reinforcing fibreglass bundle for deformation monitoring. Sensors, 19, 1745/1-1745/8 (2019) 10.3390/s19071745 IF=3.275 Q1

- Virág Á. D., Vas L. M., Bakonyi P., Halász M.: Analysing of the Yarn Pull-out Process for the Characterization of Reinforcing Woven Fabrics. Fibers and Polymers, 20, 1975-1982 (2019) 10.1007/s12221-019-8978-9 IF=1.797 Q1

- Semperger O. V., Suplicz A.: Titán-dioxid hatása az in-situ polimerizációval előállított poliamid 6 minták tulajdonságaira. in 'XXVII. Nemzetközi Gépészeti Konferencia OGÉT 2019 Nagyvárad, Románia. 2019.04.25.-2019.04.28,472-475. (2019)

- Vermes B., Czigány T.: Layup optimization and ways to improve the manufacturability of coupled composites. in 'International Conference on Composite Materials (ICCM22) Melbourne, Australia. 2019.08.11-2019.08.16,7 (2019)

- Vas L. M., Kocsis Z., Czigány T., Tamás P., Romhány G.: Novel evaluation method of acoustic emission data based on statistical fiber bundle cells. Journal of Composite Materials, 53, 2429-2446 (2019) 10.1177/0021998319826666 IF=1.972 Q3

- Kovács L., Romhány G.: Szálhullámosság hatása hosszú szálerősítésű unidirekcionális kompozit mechanikai tulajdonságaira. Polimerek, 5, 696-701 (2019)

- Szebényi G., Hliva V.: Detection of Delamination in Polymer Composites by Digital Image Correlation—Experimental Test. Polymers, 11, 523/1-523/11 (2019) 10.3390/polym11030523 IF=3.426 Q1

- Boros R., Rajamani P. K., Kovács J. G.: Combination of 3D printing and injection molding: Overmolding and overprinting. Express Polymer Letters, 13, 889-897 (2019) 10.3144/expresspolymlett.2019.77 IF=3.083 Q2

- Hliva V., Szebényi G.: Mesterséges rétegelválás modellezése polimer kompozitokban. in 'XXVII. Nemzetközi Gépészeti Konferencia (OGÉT2019) Nagyvárad, Románia. 2019.04.25-2019.04.28.,197-200 (2019)

- Semperger O. V., Őri Z., Hegedűs G., Molnár P.: Gyártástechnológiai fejlesztés nagy komplexitású, hőre lágyuló mátrixú kompozit előállítására. Polimerek, 4, 123-128 (2018)

- Kovács L., Romhány G.: Effect of variability of mechanical parameters on the deformation behaviour and failure of fibre reinforced plastic materials. in 'ECCM18 - 18th European Conference on Composite Materials Athens, Greece. 2018.06.24-2018.06.28., (2018)

- Szebényi G., Magyar B.: Effect of fibre sizing on the interlaminar properties of polyamide matrix composites. IOP Conference Series: Materials Science and Engineering, 426, 012044/1-012044/7 (2018) 10.1088/1757-899X/426/1/012044

- Hegedűs G., Czigány T.: Polimer kompozit termékek komplexitását kihasználó üvegszálas érzékelő csatlakozójának fejlesztése. in 'OGÉT 2018: XXVI. Nemzetközi Gépészeti Konferencia Marosvásárhely, Románia. 2018.04.26-2018.04.29.,179-182 (2018)

- Vermes B., Czigány T.: Kompozitok alakváltásának lehetőségei. Gép, 69, 51-54 (2018)

- Pomázi Á., Toldy A.: Égésgátolt glicerin alapú epoxigyanta kompozitok fejlesztése mérnöki alkalmazásokhoz. Polimerek, 4(2), 59-64 (2018)

- Hegedűs G., Czigány T.: Developing a glass fibre sensor for polymer technology applications. IOP Conference Series: Materials Science and Engineering, 426, 012015/1-012015/1-4 (2018) 10.1088/1757-899X/426/1/012015

- Szebényi G., Tamás-Bényei P., Sibikin I., Ageyeva T., Osváth Zs., Pásztor Sz., Iván B., Karger-Kocsis J., Czigány T.: Ɛ-kaprolaktám alkalmazása T-RTM technológiákban. in 'ERŐSÍTETT MŰANYAGOK 2018 Nemzetközi BALATON Konferencia Balatonkenese, Magyarország. 2018.05.15-2018.05.16.,7 (2018)

- Szebényi G., Faragó D., Lámfalusi Cs., Göbl R.: Interfacial adhesion improvement in carbon fiber/carbon nanotube reinforced hybrid composites by the application of a reactive hybrid resin initiated by gamma irradiation. Radiation Physics and Chemistry, 145, 111-115 (2018) 10.1016/j.radphyschem.2017.12.018 IF=1.984 Q1

- Boros R., Kannan P. R., Kovács J. G.: Thermoplastic Overmolding onto Injection-Molded and In Situ Polymerization-Based Polyamides. Materials, 11, 2140/1-2140/ (2018) 10.3390/ma11112140 IF=2.972 Q2

- Hegedűs G., Czigány T.: Analysis of the applicability of optical fibers as sensors for the structural health monitoring of polymer composites: the relationship between attenuation and the deformation of the fiber. Sensors and Actuators A: Physical, 272, 206-211 (2018) 10.1016/j.sna.2018.01.039 IF=2.739 Q2

- Forintos N., Czigány T.: Üvegszál erősítésű kompozitok deformációjának mérése szénszálak segítségével. in 'OGÉT 2017: XXV. Nemzetközi Gépészeti Konferencia Kolozsvár, Románia. 2017.04.27-2017.04.30.,147-150 (2017)

- Szebényi G., Magyar B., Iványicki T.: Comparison of static and fatigue interlaminar testing methods for continuous fiber reinforced polymer composites. Polymer Testing, 63, 307-313 (2017) 10.1016/j.polymertesting.2017.08.033 IF=2.247 Q2

- Czigány T., Forintos N., Hegedűs G.: Health monitoring of high-performance polymer composites with multifunctional fibers. in 'ICCM21 Xi'an, Kína. 2017.08.20-2017.08.25.,8 (2017)

- Szebényi G., Czigány T., Magyar B., Karger-Kocsis J.: 3D printing-assisted interphase engineering of polymer composites: Concept and feasibility. Express Polymer Letters, 11, 525-530 (2017) 10.3144/expresspolymlett.2017.50 IF=3.064 Q1

- Péter B., Hegedűs G., Czigány T.: T-RTM eljárással gyártott alkatrészek gyártási folyamatának kihívásai, különös tekintettel az erősítőanyagok kezelésére. Gép, 68, 37-42 (2017)

- Hegedűs G., Czigány T.: Optikai szálak alkalmazása polimer anyagvizsgálatokhoz. in 'OGÉT 2017: XXV. Nemzetközi Gépészeti Konferencia Kolozsvár, Románia. 2017.04.27-2017.04.30.,175-178 (2017)

- Hegedűs G., Sarkadi T., Czigány T.: Analysis of the light transmission ability of reinforcing glass fibers used in polymer composites. Materials, 10(6), 637/1-9 (2017) 10.3390/ma10060637 IF=2.467 Q2

© 2014 BME Department of Polymer Engineering - Created by: Dr. Romhány Gábor