MTA-BME Lendület Sustainable Polymers Research Group

Dr. Gergely Czél

Gergő Zsolt Marton

Dr. Kolos Molnár

Dr. Ákos Pomázi

Péter Sántha

Dr. Gábor Szebényi

Dr. Péter Tamás-Bényei

Dr. Beáta Szolnoki

Dániel István Poór

Project summary

Closing the product life cycle loop through recycling and reuse is the key to transitioning to a circular economy. This project will address the challenges of establishing a circular economy for all types of polymers, from sourcing during production to monitoring and repair during use, to recycling and functional redesign at end-of-life. The main challenge in sustainable polymer design is to create inherently recyclable thermoset polymers and recyclable thermoplastic polymer systems for structural applications. The project aims to develop recyclable vitrimer systems and thermoset polymers from potentially renewable sources for high-performance composites and self-reinforced polymer composites from ε-caprolactam for potential replacement of short-fibre reinforced polyamide 6 composites. Extending lifespan can be a relevant strategy for structural polymer composites to minimise their environmental impact. The project aims to develop durable and damage-tolerant composite structures, improve non-destructive testing methods, integrate sensors for continuous monitoring, and include healing and repair capabilities. As the mechanical recycling of thermoplastics is a well-established technology, the focus of this research is to identify sustainable recycling methods for difficult-to-recycle polymer systems for which industrial-scale solutions have not yet been developed, including innovative polymer matrices, fibre reinforcement and polymer additives. The underutilization of sustainable strategies in product design leads to the downcycling of polymer waste. We will develop value-added safe-by-design recycled and recyclable polymers and composites by upcycling and methods for predicting and modelling their properties.

Project results

Project-related publications

- Marton G. Zs., Szebényi G.: Influencing the damage process and failure behaviour of polymer composites - A short review. Express Polymer Letters, 19, 140-160 (2025) 10.3144/expresspolymlett.2025.11 IF=2.7 Q2

- Vas L. M., Slezák E., Molnár K., Ronkay F. Gy.: Advanced avrami formula and its application to describing the isothermal crystallisation of polymers. Thermochimica Acta, 746, 179950/1-179950/19 (2025) 10.1016/j.tca.2025.179950 IF=3.1 Q2

- Vas L. M., Czigány T., Tamás-Bényei P.: Development of a new method for characterize resistance to cyclic tensile load in mono and hybrid composites. Periodica Polytechnica-Mechanical Engineering, 69, 93-102 (2025) 10.3311/PPme.37831 IF=1.3 Q3

- Abdullah K. K., Molnár K.: The influence of in vitro degradation on the properties of polylactic acid electrospun fiber mats. Fibers, 13, 1-20 (2025) https://doi.org/10.3390/fib13010001 IF=4 Q2

- Toldy Andrea, Poór Dániel István, Geier Norbert, Pomázi Ákos: Recent advances and challenges in the mechanical and chemical recycling of vitrimers and fibre-reinforced vitrimer composites: A review. Composites Part B: Engineering, 306, 112760/1-112760/29 (2025) 10.1016/j.compositesb.2025.112760 IF=12.7 D1

- Du Wanrong, Orbulov I. N., Tamás-Bényei P., Wiener Cs.: Mechanical behavior of layered composite structures of aluminum foam partially filled with polyamide. Periodica Polytechnica-Mechanical Engineering, 69, 1-7 (2025) 10.3311/PPme.40446 IF=1.3 Q3

- Marton G. Zs., Balogh F., Szebényi G.: Acoustic emission analysis and signal classification for damage modes in UD carbon/epoxy composites. Express Polymer Letters, 19, 809-821 (2025) 10.3144/expresspolymlett.2025.62 IF=2.7 Q2

- Görbe Á., Marton G. Zs., Bárány T.: Acoustic emission analysis of failure processes in polyethylene and recycled tire rubber blends. Polymer Testing, 147, 108813/1-108813/9 (2025) https://doi.org/10.1016/j.polymertesting.2025.108813 IF=5 D1

- Kovács Zs., Toldy A.: Synergistic flame retardant coatings for carbon fibre-reinforced E-caprolactam-based polyamide 6 composites: fire performance and mechanical properties. Polymer Degradation and Stability, 240, 111495/1-111495/14 (2025) https://doi.org/10.1016/j.polymdegradstab.2025.111495 IF=6.3 D1

- Abdullah K. K., Molnár K.: Current trends and future prospects of integrating electrospinning with 3D printing techniques for mimicking bone extracellular matrix scaffolds. Journal of Polymer Science, 63, 1481-1504 (2025) https://doi.org/10.1002/pol.20241010 IF=3.9 Q2

- Sántha P., Tamás-Bényei P., Toldy A.: From scrap to structure: The challenges of carbon fibre recycling.

- Toldy Andrea, Poór Dániel István, Szolnoki Beáta, Geier Norbert, Pomázi Ákos: Synergistic flame retardancy of carbon fibre-reinforced polyimine vitrimer composites via vitrimer-based intumescent coating. Composites Part A: Applied Science and Manufacturing, 198, 109135/1-109135/13 (2025) 10.1016/j.compositesa.2025.109135 IF=8.1 Q1

- Toldy A.: Safe and sustainable-by-design: Redefining polymer engineering for a greener future.

- Suwarta P., Wisnom M. R., Fotouhi M., Wu X., Czél G.: Pseudo-ductile compressive behaviour of unidirectional thin-ply carbon /glass fibre-epoxy hybrid composites. Composites Part A: Applied Science and Manufacturing, 195, 108877/1-108877/15 (2025) 10.1016/j.compositesa.2025.108877 IF=8.1 Q1

- Dózsa G., Sántha P., Tamás-Bényei P.: Fehér töltőanyagot tartalmazó gumikeverékek fejlesztése. Polimerek, 10, 34-40 (2024)

- Vajtai L., Nemes N. M., del Puerto Morales M., Molnár K., Pinke B. G., Simon F.: Incidence of the Brownian Relaxation Process on the Magnetic Properties of Ferrofluids. Nanomaterials, 14, 634/1-634/15 (2024) 10.3390/nano14070634 IF=4.4 Q2

- Kovács Zs., Toldy A.: Development of flame retardant coatings containing hexaphenoxycyclotriphosphazene and expandable graphite for carbon fibre-reinforced polyamide 6 composites. Polymer Degradation and Stability, 230, 111017 (2024) 10.1016/j.polymdegradstab.2024.111017 IF=6.3 D1

- Gere D., Pomázi F., Szöllősi A., Jahanpeyma P., Ermilov A. A., Baranya S., Toldy A.: Mikroműanyag szennyezés vizsgálata a Duna budapesti szakaszán. Polimerek, 2, 66-72 (2024)

- Szebényi G., Marton G. Zs., Romhány G.: Damage localization in designed failure composites. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország. 2024.07.02-2024.07.05.,156-160 (2024)

- Kovács Zs., Toldy A.: Flame retardant coatings for E-caprolactam-based self-reinforced polyamide 6 composites. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország. 2024.07.02.-05.,989-995 (2024)

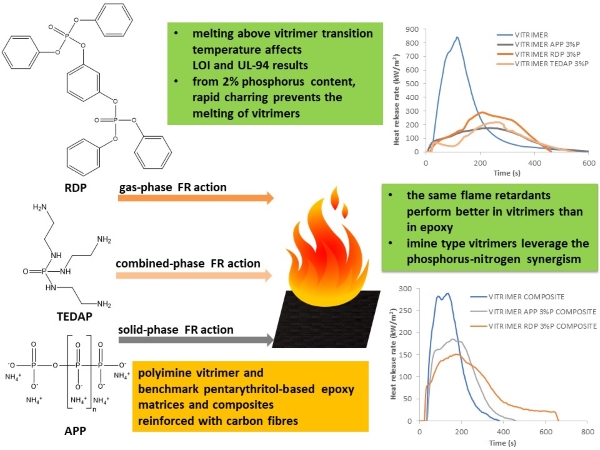

- Toldy A., Poór D. I., Szolnoki B., Devecser B., Geier N., Pomázi Á.: Comparative study of flame retardancy in polyimine vitrimers and composites: Evaluating additive and reactive flame retardants acting via gas-, solid-, and combined-phase mechanisms. Journal of Materials Science & Technology, 196, 101-111 (2024) 10.1016/j.jmst.2024.01.047 IF=11.2 D1

- Budavári B., Karancsi Á., Pinke B. G., Pállinger É., Juriga-Tóth K., Király M., Szász Zs., Voszka I., Molnár K., Kőhidai L., Jedlovszky-Hajdú A., S Nagy K.: Long-term shelf-life liposomes for delivery of prednisolone and budesonide. Journal of Molecular Liquids, 394, 123756/1-123756/13 (2024) 10.1016/j.molliq.2023.123756 IF=5.3 Q1

- Marton G. Zs., Szebényi G.: The effect of pattern width on the properties and behavior of interfacially engineered composites with designed failure. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország. 2024.07.02-2024.07.05.,1438-1443 (2024)

- Kovács Zs., Toldy A.: Flame retardancy via in-mould coating and durability of flame retardants after mechanical recycling in all-polyamide composites prepared by in situ polymerisation. Macromolecular Materials and Engineering, 310, 202400325/1-202400325/12 (2024) 10.1002/mame.202400325 IF=4.2 Q2

- Poór D. I., Tobey M., Taynton P., Pomázi Á., Toldy A., Geier N.: A comparative machinability analysis of polyimine vitrimer, epoxy and polycarbonate polymers through orthogonal machining experiments. International Journal of Advanced Manufacturing Technology, 131, 1361-1376 (2024) 10.1007/s00170-024-13087-9 IF=2.9 Q2

- Wisnom M.R., Pimenta S., Shaffer M.S.P., Robinson P., Potter K.D., Hamerton I., Czél G., Jalalvand M., Fotouhi M., Anthony D.B., Yu H., Longana M.L., Wu X., Bismarck A.: High performance ductile and pseudo-ductile polymer matrix composites: A review. Composites Part A: Applied Science and Manufacturing, 181, 108029/1-108029/39 (2024) 10.1016/j.compositesa.2024.108029 IF=8.1 Q1

- Marton G. Zs., Fendrik Á., Szebényi G.: Manufacturing of composites with designed failure. IOP Conference Series: Materials Science and Engineering, 1313, 012014/1-012014/9 (2024) 10.1088/1757-899X/1313/1/012014

- Molnár K.: Combination of nanofibers with 3D-printed or 4D-printed structures. Express Polymer Letters, 18, 243-244 (2024) 10.3144/expresspolymlett.2024.17 IF=2.7 Q2

- Czél G.: Development of sandwich test coupons with continuous protective layers for accurate determination of the tensile failure strain of unidirectional carbon fibre reinforced composites. Composites Part A: Applied Science and Manufacturing, 187, 108440/1-108440/12 (2024) 10.1016/j.compositesa.2024.108440 IF=8.1 Q1

- Virág Á. D., Juhász Zs., Kossa A., Molnár K.: Combining oscillatory shear rheometry and dynamic mechanical analysis to obtain wide-frequency master curves. Polymer, 295, 126742/1-126742/11 (2024) https://doi.org/10.1016/j.polymer.2024.126742 IF=4.1 Q2

- Pomázi Á., Poór D. I., Geier N., Toldy A.: Optimising recycling processes for polyimine-based vitrimer carbon fibre-reinforced composites: A comparative study on reinforcement recovery and material properties. Materials, 17, 2372/1-2372/15 (2024) 10.3390/ma17102372 IF=3.1 Q1

- Tamás-Bényei P.: Kompozitok újrahasznosítási lehetőségei. Visszanyert szénszálak. Élet és Tudomány, 39, 1222-1224 (2024)

- Juhász Á. Gy., Nanys M., Pinke B., Fadel A., Godzierz M., Juriga-Tóth K., Molnár K., Juriga D., Jedlovszky-Hajdú A.: Formation of three-dimensional polysuccinimide electrospun fiber meshes induced by the combination of CaCl2 and humidity. Macromolecular Rapid Communications, , 2300625/1-2300625/12 (2024) 10.1002/marc.202300625 IF=4.2 Q2

- Nemes-Károly I., Szebényi G.: Development of sintered all-UHMWPE composites for joint implant sockets. in 'ECCM21 - 21st European Conference on Composite Materials Nantes, Franciaország. 2024.07.02-2024.07.05.,1119-1125 (2024)

- Kovács Zs., Toldy A.: Synergistic flame retardant coatings for carbon fibre-reinforced polyamide 6 composites based on expandable graphite, red phosphorus, and magnesium oxide. Polymer Degradation and Stability, 222, 110696/1-110696/11 (2024) 10.1016/j.polymdegradstab.2024.110696 IF=6.3 D1

- Czél G.: Direct comparison of novel unidirectional sandwich coupon designs for accurate tensile failure strain determination of carbon fibre epoxy material. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország . 2024.07.02.-05.,Vol 4. 25-32 (2024)

- Gere D., Toldy A.: Az EU két éve betiltotta az oxidatív úton lebomló, széttöredező polimerből készülttermékeket, amelyek hozzájárultak a mikroműanyagok keletkezéséhez.

- Tamás-Bényei P.: The effect of salt water on the properties of basalt fibre reinforced composites. Acta Materialia Transylvanica, 6., 105-113 (2023) 10.33924/amt-2023-02-08

- Toldy A.: Challenges and opportunities of polymer recycling in the changing landscape of European legislation.

- Zielinski D., Szpecht A., Pomázi Á., Kovács Zs., Szolnoki B., Pinke B., Toldy A., Smiglak M.: Multifunctional modifying systems based on ionic liquids for epoxy resin systems and composites. Applied Sciences-Basel, 13, 10661/1-10661/14 (2023) 10.3390/app131910661 IF=2.5 Q1