The utilization of the rheological and structural characteristics of polymer solutions and melts for their efficient processing

Dr. András Suplicz

Dr. Dániel Török

Dr. Ábris Dávid Virág

Project summary

The rheological behavior of polymer solutions and melts has long been of great scientific interest. The flow properties of these materials originate from the macromolecular structure (structural viscosity). Various models can be used to infer the molecular structure from the rheological behavior of the material. One of the aims of the project is to investigate the applicability of these models and validate them with actual molecular weight measurements. The modeling of these fluids is complicated because they are highly non-Newtonian in nature, are compressible, have timedependent flow characteristics (relaxation occurs), also show a kind of shape memory, and can be stretched even in a liquid state (with tensile stresses). We see these features not as obstacles, but as factors from which we can take advantage of at the processing of thermoplastics. For example, by applying suitable shear forces, gels can be processed into nanofibers, or even self-cleaning of the sprue can be achieved at injection molding. We plan to apply the relationships between rheological behavior and material structure, explored in this research, in three areas: continuous fibers (especially nanofibers), injection molding, and thermoplastic matrix composites. In the research, special emphasis is placed on how the processing technology itself changes the molecular weight and flowability of the raw material, as well as how we can take these into account, e.g. during simulations. It is also an interesting question how the structure of the material changes (molecular weight, crystallinity, microplastic formation) during the recycling, reprocessing, or even aging and decomposition of polymers.

Project results

Project-related publications

- Tóth Cs., Molnár K., Virág Á. D.: Short fiber reinforcement in material extrusion 3D printing: A meta-analysis review with insights into sustainable alternatives. Polymer Composites, , 29850/1-29850/1-39 (2025) https://doi.org/10.1002/pc.29850 IF=4.8 Q1

- Krizsma Sz. G., Suplicz A.: Novel Coupled Simulation Method and Comprehensive Metrology to Enhance the Application of Prototype Injection Moulds. , 165, 179-188 (2025) https://doi.org/10.4028/p-q56eQa

- Abdullah K. K., Molnár K.: The influence of in vitro degradation on the properties of polylactic acid electrospun fiber mats. Fibers, 13, 1-20 (2025) https://doi.org/10.3390/fib13010001 IF=4 Q2

- Tatár B., Homlok R., Mészáros L.: Enhancing the shape memory performance of self-reinforced cross-linked polyethylene composites by the optimization of the production temperature. Nuclear Engineering and Technology, 57, 103617/1-103617/8 (2025) 10.1016/j.net.2025.103617

- Abdullah K. K., Molnár K.: Current trends and future prospects of integrating electrospinning with 3D printing techniques for mimicking bone extracellular matrix scaffolds. Journal of Polymer Science, 63, 1481-1504 (2025) https://doi.org/10.1002/pol.20241010 IF=3.9 Q2

- Tatár B., Tóth E., Molnár K., Mészáros L.: Shape memory characteristics of injection molded, cross-linked all-polyethylene composites. Radiation Physics and Chemistry, 226, 112290/1-112290/9 (2025) 10.1016/j.radphyschem.2024.112290 IF=2.8 Q1

- Vas L. M., Slezák E., Molnár K., Ronkay F. Gy.: Advanced avrami formula and its application to describing the isothermal crystallisation of polymers. Thermochimica Acta, 746, 179950/1-179950/19 (2025) 10.1016/j.tca.2025.179950 IF=3.1 Q2

- Tóth Cs., Molnár K., Virág Á. D.: A bioműanyag termékek jövője orvostechnikai alkalmazásokban. Műanyag- és Gumiipari Évkönyv, 23, 94-100 (2025)

- Krizsma Sz. G., Suplicz A., Gere D.: Customised production of injection moulded parts from recycled materials using rapid tooling approach and coupled injection moulding-thermal and mechanical simulation. Results in Engineering, 26, 105272/1-105272/15 (2025) https://doi.org/10.1016/j.rineng.2025.105272 IF=6 D1

- Párizs R. D., Török D.: An experimental study on the application of reinforcement learning in injection molding in the spirit of Industry 4.0. Applied Soft Computing, 167, 112236/1-112236/14 (2024) 10.1016/j.asoc.2024.112236 IF=7.2 D1

- Juhász Á. Gy., Nanys M., Pinke B., Fadel A., Godzierz M., Juriga-Tóth K., Molnár K., Juriga D., Jedlovszky-Hajdú A.: Formation of three-dimensional polysuccinimide electrospun fiber meshes induced by the combination of CaCl2 and humidity. Macromolecular Rapid Communications, , 2300625/1-2300625/12 (2024) 10.1002/marc.202300625 IF=4.2 Q2

- Virág Á. D., Tóth Cs., Polyák P., Musioł M., Molnár K.: Tailoring the mechanical and rheological properties of poly(lactic acid) by sterilizing UV-C irradiation. International Journal of Biological Macromolecules, 277, 134247/1-134247/12 (2024) https://doi.org/10.1016/j.ijbiomac.2024.134247 IF=7.7 D1

- Virág Á. D., Juhász Zs., Kossa A., Molnár K.: Combining oscillatory shear rheometry and dynamic mechanical analysis to obtain wide-frequency master curves. Polymer, 295, 126742/1-126742/11 (2024) https://doi.org/10.1016/j.polymer.2024.126742 IF=4.1 Q2

- Vajtai L., Nemes N. M., del Puerto Morales M., Molnár K., Pinke B. G., Simon F.: Incidence of the Brownian Relaxation Process on the Magnetic Properties of Ferrofluids. Nanomaterials, 14, 634/1-634/15 (2024) 10.3390/nano14070634 IF=4.4 Q2

- Virág Á. D., Tóth Cs., Mészáros L., Juhász Zs., Bezerédi Á., Petrény R.: Optimizing the injection molding process for thermally and electrically conductive, carbon fiber and carbon nanotube-reinforced poly(lactic acid) hybrid composites with enhanced mechanical properties. Journal of Applied Polymer Science, 141, e56148/1-e56148/11 (2024) https://doi.org/10.1002/app.56148 IF=2.7 Q2

- Virág Á. D., Molnár K.: Fertőtlenítő UV-C sugárzás politejsavra gyakorolt roncsoló hatása. Polimerek, 10, 130-136 (2024)

- Krizsma Sz., Suplicz A.: Comprehensive Measurement and Simulation of Prototype Injection Moulds. Defect and Diffusion Forum, 435, 141-150 (2024) 10.4028/p-Y3Lvjr

- Tatár B., Mészáros L.: Shape memory characteristics of injection molded poly(lactic acid) multiscale hybrid composites. ACS Omega, 9, 46960-46967 (2024) 10.1021/acsomega.4c06592

- Krizsma Sz., Széplaki P., Suplicz A.: Coupled injection moulding simulation–thermal and mechanical simulation method to analyse the operational behaviour of additively manufactured polymeric injection moulds. Results in Engineering, 23, 102558/1-102558/16 (2024) https://doi.org/10.1016/j.rineng.2024.102558 IF=6 D1

- Virág Á. D., Molnár K.: Modelling the time-dependent mechanical properties of thermoplastic and thermosetting polymers with Gumbel distribution functions. Polymer, 312, 127642/1-127642/12 (2024) https://doi.org/10.1016/j.polymer.2024.127642 IF=4.1 Q2

- Budavári B., Karancsi Á., Pinke B. G., Pállinger É., Juriga-Tóth K., Király M., Szász Zs., Voszka I., Molnár K., Kőhidai L., Jedlovszky-Hajdú A., S Nagy K.: Long-term shelf-life liposomes for delivery of prednisolone and budesonide. Journal of Molecular Liquids, 394, 123756/1-123756/13 (2024) 10.1016/j.molliq.2023.123756 IF=5.3 Q1

- Virág Á. D., Suplicz A., Török D.: Prediction of the thermal degradation–induced colour change of acrylonitrile butadiene styrene products as a function of temperature and titanium dioxide content. Results in Engineering, 24, 103505/1-103505/11 (2024) https://doi.org/10.1016/j.rineng.2024.103505 IF=6 D1

- Széplaki P., Suplicz A.: Poliamid 6 mátrixú kompozit szendvicsszerkezetek gyárthatósága T-RTM technológiával. Polimerek, 10, 226-232 (2024)

- Krizsma Sz., Suplicz A.: Analysis of the applicability and state monitoring of material extrusion–printed acrylonitrile butadiene styrene injection mould inserts with different infill levels. Materials Today Communications, 35, 106294/1-106294/12 (2023) 10.1016/j.mtcomm.2023.106294 IF=3.7 Q2

- Virág Á. D., Tóth Cs., Molnár K.: Photodegradation of polylactic acid: Characterisation of glassy and melt behaviour as a function of molecular weight. International Journal of Biological Macromolecules, 252, 126336/1-126336/14 (2023) 10.1016/j.ijbiomac.2023.126336 IF=7.7 D1

- Semperger O. V., Suplicz A.: The degradation during recycling of polyamide 6 produced by anionic ring‑opening polymerization of ε‑caprolactam. Scientific Reports, 13, 17130/1-17130/11 (2023) doi.org/10.1038/s41598-023-44314-0 IF=3.8 Q1

- Kara Y., Kovács N. K., Nagy-György P., Boros R., Molnár K.: A novel method and printhead for 3D printing combined nano-/microfiber solid structures. Additive Manufacturing, 61, 103315/1-103315/13 (2023) 10.1016/j.addma.2022.103315 IF=10.3 D1

- Krizsma Sz. G., Suplicz A.: Comprehensive in-mould state monitoring of material jetting additively manufactured and machined aluminium injection moulds. Journal of Manufacturing Processes, 84, 1298-1309 (2022) 10.1016/j.jmapro.2022.10.070 IF=6.2 Q2

- Fris D. R., Szabó F.: Investigation of segregation in the runner system during injection moulding. IOP Conference Series: Materials Science and Engineering, 1246, 012029/1-012029/8 (2022) 10.1088/1757-899X/1246/1/012029

- Mészáros L., Tatár B., Toth K., Földes A., S. Nagy K., Jedlovszky-Hajdú A., Tóth T., Molnár K.: Novel, injection molded all-polyethylene composites for potential biomedical implant applications. Journal of Materials Research and Technology, 17, 743-755 (2022) 10.1016/j.jmrt.2022.01.051 IF=6.4 D1

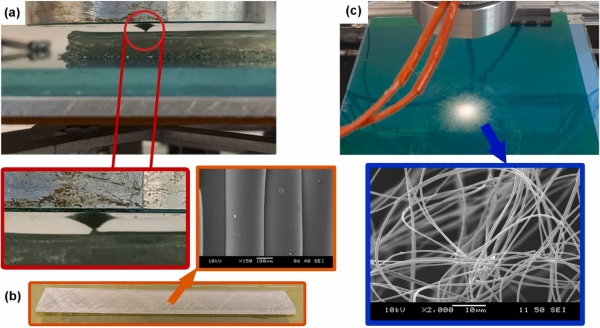

- Kara Y., Molnar K: Development of single-polypropylene composites interleaved with MWCNT-doped melt-blown fine fiber mats. Polymer Composites, 43, 5208-5221 (2022) https://doi.org/10.1002/pc.26812 IF=5.2 Q1

- Krizsma Sz. G., Suplicz A.: State-monitoring and product quality measurement of additively manufactured injection mould inserts. IOP Conference Series: Materials Science and Engineering, 1246, 012020/1-012020/8 (2022) 10.1088/1757-899X/1246/1/012020

- Semperger O. V., Török D., Suplicz A.: Development and Analysis of an In-Mold Coating Procedure for Thermoplastic Resin Transfer Molding to Produce PA6 Composites with a Multifunctional Surface. Periodica Polytechnica-Mechanical Engineering, 66, 350-360 (2022) 10.3311/PPme.21048 IF=1.3

- Kara Y., Molnár K.: Decomposition behavior of stereocomplex PLA melt-blown fine fiber mats in water and in compost. Journal of Polymers and the Environment, 31, 1398-1414 (2022) 10.1007/s10924-022-02694-w IF=5.3 Q1