Investigation of additive manufactured 3D reinforcing framework structure as insert in injection molded composite products

Dr. András Suplicz

Dr. Ferenc Szabó

Project summary

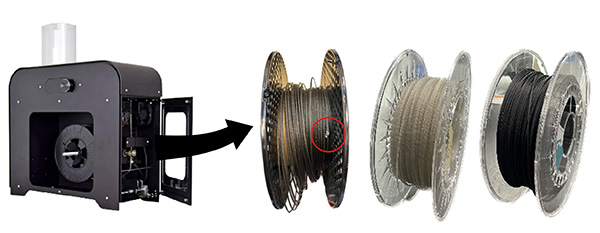

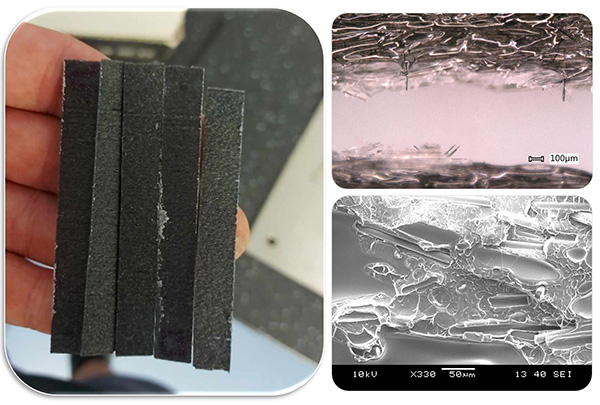

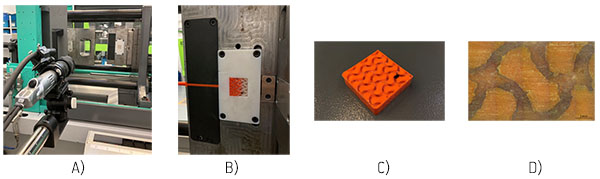

Nowadays polymer products are more and more often used in parts of critical safety and parts subjected to high loads. As a result, fiber-reinforced composites receive more and more attention. Their mechanical properties are anisotropic, and depend on the orientation of the reinforcement. Fiber-reinforced materials can be injection molded; here the orientation of the fibers is basically determined by the flow conditions. As a result, the part often needs to have increased wall thickness or reinforcing ribs to satisfy mechanical requirements. Ribs, however, mean extra material, weight and cost. Another problem is the weld lines, which result in the forming of mechanically critical areas. A further problem is fiber breaking, caused by the technology. The goal of the project is to create a complex design methodology with which a tailor-made reinforcing structure can be made in injection molded parts as a separate step, by 3D printing. Its advantage is that the characteristics of the reinforcing structure (orientation, fiber content etc.) can be made independent of flow conditions and can be changed in each point according to the load. Another advantage of the procedure is that fiber shortening can also be greatly reduced, thus the reinforcing effect is increased and recyclability by remelting is better facilitated. A further goal is to apply and extend the developed method for biopolymers like Poly(Lactic Acid) (PLA), the one which is mostly in focus for biopolymer research.

Project results

Project-related publications

- Krizsma Sz., Mészáros L., Kovács N. K., Suplicz A.: Expanding the applicability of material jetting–printed photopolymer prototype injection moulds by gamma irradiation post-treatment. Journal of Manufacturing Processes, 134, 135-145 (2025) https://doi.org/10.1016/j.jmapro.2024.12.037 IF=6.1 Q1

- Csézi G., Tábi T.: Mechanical and morphological properties of uniaxially oriented and heat-treated poly(lactic acid)/poly(butylene adipate-co-terephthalate) blends. Advances in Polymer Technology, , 7082244/1-7082244/11 (2025) 10.1155/adv/7082244 IF=2 Q3

- Szederkényi B., Rácz I., Kovács N.K., Czigány T.: Finite element modelling of continuous fiber–reinforced composites produced by automated manufacturing. IOP Conference Series: Materials Science and Engineering, 1313, 012002/1-012002/8 (2024) 10.1088/1757-899X/1313/1/012002

- Tábi T., Gere D., Csézi G., Pölöskei K.: Influence of Epoxidized Natural Rubber of the thermoformability of Poly(Lactic Acid) biopolymer films using elevated temperature ball burst tests. Journal of Thermal Analysis and Calorimetry, 149, 75-87 (2024) 10.1007/s10973-023-12712-1 IF=3 Q2

- Dragan V. K., Petrovics N., Kirchkeszner Cs., Tábi T., Szabó B. S., Eke Zs.: The kinetics of swelling and migration: A case study of plasticized polylactic acid food contact plastics tested with ethanolic food simulants. Express Polymer Letters, 18, 391-405 (2024) 10.3144/expresspolymlett.2024.29 IF=2.7 Q2

- Krizsma Sz., Széplaki P., Suplicz A.: Coupled injection moulding simulation–thermal and mechanical simulation method to analyse the operational behaviour of additively manufactured polymeric injection moulds. Results in Engineering, 23, 102558/1-102558/16 (2024) https://doi.org/10.1016/j.rineng.2024.102558 IF=6 D1

- Tóth Cs., Vas L. M., Kovács N. K.: Achieving gradual failure under bending by the layering design of 3D printed continuous fiber reinforced composites. Results in Engineering, 22, 102075/1-102075/8 (2024) https://doi.org/10.1016/j.rineng.2024.102075 IF=6 D1

- Szederkényi B., Czigány T., Kovács N. K.: Investigation of continuous fiber–reinforced triply periodic minimal surfaces (TPMS) for high-performance energy absorption applications. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország. 2024.06.02-2024.06.05.,1651-1658 (2024)

- Tóth Cs., Virág Á. D., Vas L. M., Kovács N. K.: Prediction and analysis of flexural stiffness for 3D-printed continuous fiber–reinforced composites with different matrix fill ratios and layer orders. Polymer Testing, 135, 108459/1-108459/11 (2024) https://doi.org/10.1016/j.polymertesting.2024.108459 IF=5 D1

- Párizs R. D., Török D.: An experimental study on the application of reinforcement learning in injection molding in the spirit of Industry 4.0. Applied Soft Computing, 167, 112236/1-112236/14 (2024) 10.1016/j.asoc.2024.112236 IF=7.2 D1

- Tóth Cs., Lukács N. L., Kovács N. K.: The role of the fiber–matrix interface in the tensile properties of short fiber–reinforced 3D-printed polylactic acid composites. Polymer Composites, 45, 13589-13602 (2024) https://doi.org/10.1002/pc.28720 IF=4.8 Q1

- Krizsma Sz., Suplicz A.: Analysis of the applicability and state monitoring of material extrusion–printed acrylonitrile butadiene styrene injection mould inserts with different infill levels. Materials Today Communications, 35, 106294/1-106294/12 (2023) 10.1016/j.mtcomm.2023.106294 IF=3.7 Q2

- Kara Y., Kovács N. K., Nagy-György P., Boros R., Molnár K.: A novel method and printhead for 3D printing combined nano-/microfiber solid structures. Additive Manufacturing, 61, 103315/1-103315/13 (2023) 10.1016/j.addma.2022.103315 IF=10.3 D1

- Hajagos Sz., Zink B.: Polimer fröccsöntő inzertek deformációs viselkedésének modellezése numerikus számításokkal. in 'XXXI. Nemzetközi Gépészeti Konferencia OGÉT Temesvár, Románia. 2023.04.27-2023.04.30.,183-188 (2023)

- Krizsma Sz., Suplicz A.: Prototípus fröccsöntő szerszámok üzem közbeni állapotfelügyelete és termékminőség vizsgálata. in 'XXXI. Nemzetközi Gépészeti Konferencia Temesvár, Románia. 2023.04.17-2023.04.30.,323-328 (2023)

- Kiss B., Párizs R. D., Tóth Cs., Török D., Kovács N. K.: Anyagextrúzió alapú additív gyártástechnológiával készült termékek anizotróp viselkedésének elemzése. Polimerek, 5, 155-160 (2023)

- Tábi T.: Háromfázisú bioműanyag keverékek vizsgálata. in 'XXXI. Nemzetközi Gépészeti Konferencia (OGÉT 2023) Temesvár, Románia. 2023.04.27-2023.04.30.,460-465 (2023)

- Széplaki P., Szabó F.: Fröccsöntő szerszám inzertek deformációinak mérése és vizsgálata gyártási ciklus közben. in 'OGÉT 2023 : XXXI. Nemzetközi Gépészeti Konferencia Temesvár, Románia. 2023.04.27- 2023.04.30,450-453 (2023)

- Kotrocz L., Bakonyi P.: Investigation the temperature-dependent surface mechanical properties of PolyJet printed samples by cyclic indentation testing in a DMA system. Results in Materials, 17, 100360/1-100360/8 (2023) 10.1016/j.rinma.2022.100360

- Csézi G., Tábi T.: Hőkezelési hőmérséklet hatása a nyújtott politejsav tulajdonságaira. in 'XXXI. Nemzetközi Gépészeti Konferencia (OGÉT 2023) Temesvár, Románia. 2023.04.27-2023.04.30.,75-80 (2023)

- Krizsma Sz. G., Suplicz A.: Monitoring and modelling the deformation of an aluminium prototype mould insert under different injection moulding and clamping conditions. Results in Engineering, 20, 101556/1-101556/13 (2023) 10.1016/j.rineng.2023.101556 IF=6 D1

- Petrovics N., Kirchkeszner Cs., Patkó A., Tábi T., Magyar N., Kovácsné Székely I., Szabó B. S., Nyiri Z., Eke Zs.: Effect of crystallinity on the migration of plastic additives from polylactic acid-based food contact plastics. Food Packaging and Shelf Life, 36, 101054/1-101054/11 (2023) 10.1016/j.fpsl.2023.101054 IF=8.5 D1

- Párizs R. D., Török D., Ageyeva T., Kovács J. G.: Machine learning in injection molding: An industry 4.0 method of quality prediction. Sensors, 22, 2704/1-2704/16 (2022) 10.3390/s22072704 IF=3.9 Q2

- Tóth Cs., Kovács N. K.: Comparison of the accuracy of analytical models for basalt fiber–reinforced poly(lactic acid) composites prepared by injection molding and fused filament fabrication. International Journal of Advanced Manufacturing Technology, 121, 3999–4010 (2022) 10.1007/s00170-022-09572-8 IF=3.4 Q2

- Tábi T.: Talkum hatása a politejsav biopolimer tulajdonságaira. in 'XXX. Nemzetközi Gépészeti Konferencia (OGÉT 2022) Székelyudvarhely, Románia. 2022.04.21-2022.04.24.,5 (2022)

- Tóth Cs., Kovács N. K.: Development of a Novel Hybrid Manufacturing Technology For Continuous Fiber-Reinforced Thermo-Plastic Composites. Acta Materialia Transylvanica, 5, 39-44 (2022) 10.33924/amt-2022-01-09

- Krizsma Sz. G., Suplicz A.: Comprehensive in-mould state monitoring of material jetting additively manufactured and machined aluminium injection moulds. Journal of Manufacturing Processes, 84, 1298-1309 (2022) 10.1016/j.jmapro.2022.10.070 IF=6.2 Q2

- Semperger O. V., Suplicz A.: The effect of the titanium dioxide nanoparticles on the morphology and degradation of polyamide 6 prepared by anionic ring-opening polymerization. Polymer Engineering and Science, 62, 2079-2088 (2022) 10.1002/pen.25990 IF=3.2 Q2

- Petrény R., Tóth Cs., Mészáros L., Horváth A.: Development of electrically conductive hybrid composites with a poly(lactic acid) matrix, with enhanced toughness for injection molding, and material extrusion-based additive manufacturing. Heliyon, 8, e10287/1-e10287/8 (2022) 10.1016/j.heliyon.2022.e10287 IF=4 Q2

- Tábi T., Ageyeva T., Kovács J. G.: The influence of nucleating agents, plasticizers, and molding conditions on the properties of injection molded PLA products. Materials Today Communications, 32, 103936/1-103936/8 (2022) 10.1016/j.mtcomm.2022.103936 IF=3.8 Q2

- Petrovics N., Kirchkeszner Cs., Tábi T., Magyar N., Kovácsné Székely I., Szabó B. S., Nyiri Z., Eke Zs.: Effect of temperature and plasticizer content of polypropylene and polylactic acid on migration kinetics into isooctane and 95 v/v% ethanol as alternative fatty food simulants. Food Packaging and Shelf Life, 33, 100916/1-100916/10 (2022) 10.1016/j.fpsl.2022.100916 IF=8 D1

- Tábi T., Pölöskei K.: The effect of processing parameters and Calcium-stearate on the ejection process of injection molded Poly(Lactic Acid) products. Periodica Polytechnica-Mechanical Engineering, 66, 17-25 (2022) 10.3311/PPme.18246 IF=1.3

- Ageyeva T., Kovács J. G., Tábi T.: Comparison of the efficiency of the most effective heterogeneous nucleating agents for Poly(lactic acid). Journal of Thermal Analysis and Calorimetry, 147, 8199-8211 (2022) 10.1007/s10973-021-11145-y IF=4.4 Q1

- Krizsma Sz. G., Suplicz A.: State-monitoring and product quality measurement of additively manufactured injection mould inserts. IOP Conference Series: Materials Science and Engineering, 1246, 012020/1-012020/8 (2022) 10.1088/1757-899X/1246/1/012020

- Krizsma Sz. G., Suplicz A.: Additív gyártástechnológiával előállított fröccsöntő szerszámbetétek üzem közbeni deformációinak vizsgálata. Polimerek, 7, 155-160 (2021)

- Kirchkeszner Cs., Petrovics N., Tábi T., Magyar N., Kovács J., Szabó B. S., Nyiri Z., Eke Zs.: Swelling as a promoter of migration of plastic additives in the interaction of fatty food simulants with polylactic acid- and polypropylene-based plastics. Food Control, 132, 108354/1-108354/12 (2021) 10.1016/j.foodcont.2021.108354 IF=6.652 Q1

- Tábi T.: Fröccsöntött politejsav biopolimer sorozatgyárthatóságának elemzése. in 'XXIX. Nemzetközi Gépészeti Konferencia (OGÉT 2021) Románia. 2021.04.23.,200-203 (2021)

- Tábi T.: Tények és tévhitek a biopolimerekkel kapcsolatban - I. rész (másodközlés). Polimerek, 7, 298-301 (2021)

- Tábi T.: Tények és tévhitek a biopolimerekkel kapcsolatban - II. rész. Biohulladék, 14, 21-26 (2021)

- Csézi G., Tábi T.: Orientált biopolimer szerkezetek vizsgálata. in 'XXIX. Nemzetközi Gépészeti Konferencia (OGÉT 2021) Románia. 2021.04.23.,101-105 (2021)

- Tábi T.: Tények és tévhitek a biopolimerekkel kapcsolatban - II. rész (másodközlés). Polimerek, 7, 337-340 (2021)

- Krizsma Sz. G., Kovács N. K., Kovács J. G., Suplicz A.: In-situ monitoring of deformation in rapid prototyped injection molds. Additive Manufacturing, 42, 102001/1-102001/8 (2021) 10.1016/j.addma.2021.102001 IF=11.632 D1

- Tábi T., Ageyeva T., Kovács J. G.: Improving the ductility and heat deflection temperature of injection molded Poly(lactic acid) products: A comprehensive review. Polymer Testing, 101, 107282/1-107282/36 (2021) 10.1016/j.polymertesting.2021.107282 IF=4.931 D1

- Szabó F., Suplicz A., Kovács J. G.: Development of injection molding simulation algorithms that take into account segregation. Powder Technology, 389, 368-375 (2021) 10.1016/j.powtec.2021.05.053 IF=5.64 Q1

- Semperger O. V., Pomlényi P., Suplicz A.: Felület-bevonatolási eljárás T-RTM technológiához. Polimerek, 7, 186-192 (2021)

- Széplaki P., Hajagos Sz., Zink B., Szabó F.: Fröccsöntött termékben elhelyezett fotopolimer inzert hőtanának és deformációjának vizsgálata. in 'XXIX. Nemzetközi Gépészeti Konferencia OGÉT Online. 2021.04.23.,196-199 (2021)