The development of increased energy absorption foam structures

Project ID:

K 132462

Supported by:

Hungarian National Research, Development and Innovation Office (NKFIH)

Term:

1 December 2019 - 30 November 2023

Supervisor (BME):

Prof. Dr. Tibor Czigány

Dr. Márton Tomin

Participant researchers (BME):

Dr. Márton Tomin

Dr. Péter Tamás-Bényei

Dr. Katalin Litauszki

Dr. Dániel Gere

Project summary

The goal of the project is to develop polymer foam structures and analyze their energy absorption mechanism. We will pay special attention to the relationships between the structure and energy absorption capability of single-layer and multi-layer polymer foam structures—this will be examined with the use of non-biodegradable polymer foams and new, biodegradable polymer foams. These results are indispensable for the engineering application of foamed polymer products, such as energy absorption covers in vehicles, packaging of household appliances, and protective gear for martial arts and other fighting sports. The safety of passengers is of paramount importance in vehicles, as is the safety of people outside the vehicle. This is especially true for autonomous cars. Similarly, the safety of athletes, avoiding injury is also very important, that is why various foam structures are used in many areas in protective gear, or for a surface where sports activity can be safely done. Since currently it is difficult to recycle foams made up of several layers of different thermoplastic layers, we will analyze the possibility of recycling the different layers together. Since environmental directives are getting stricter and stricter, the biopolymer foam we plan to develop may provide a good alternative to currently used non-biodegradable foams.

Project results

Section 1

1 December 2019 - 30 November 2020

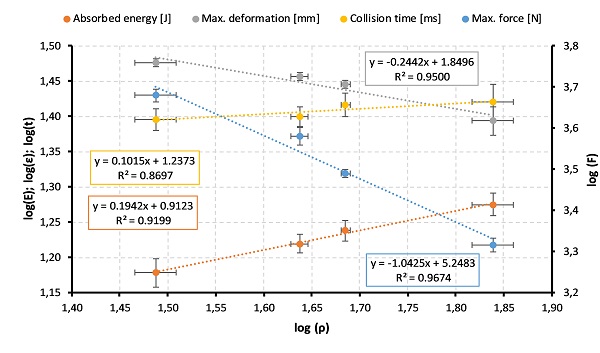

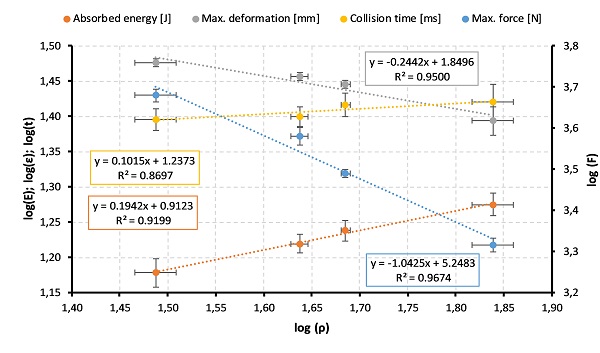

In the first research period, we performed complex mechanical, microscopic, and morphological tests on different cross-linked polyethylene (X-PE), ethylene-vinyl-acetate copolymer (EVA) and polyurethane (rebonded PUR) foam sheets of various types, thicknesses and densities. Based on compression set tests, we showed the effect of cell structure (average cell size, cell wall thickness) on the recovery capability of polymer foams. We also showed that closed-cell and open-cell foams react differently to compression. Our research on the complex characterization of XPE foams showed that the relationship between density and mechanical properties (compressive strength, energy absorption, shock absorbance, and recovery capability) can be approximated well with the power law. Based on several falling weight impact tests performed with different parameters (impact energy, impactor geometry, impact velocity), we concluded that repeated impacts impair the dynamic properties of foams but this deterioration of properties depends on foam type. Closed-cell foams are more resistant in terms of energy absorption, while open-cell foams are more resistant in terms of impact damping. With scanning electron microscopy, we showed that the reduction in impact damping in the case of microcellular EVA foams comes from the viscoelastic, time-dependent properties of polymers and can be attributed to delayed elastic deformation. In contrast, the cell structure of macrocellular XPE foams suffers permanent, irreversible deformation. We have started the production, testing, and evaluation of biopolymer-based foams. We produced foam structures using different types of polylactic acid (PLA) at different processing temperatures. We investigated exothermic and various endothermic chemical foaming agents and the effect of foaming agent content on cell structure and foam density.

Results of falling weight impact tests: the dependence of absorbed energy, maximum force, maximum deformation, and contact time on density in the case of a 30 mm thick XPE foam

Section 2

1 December 2020 - 30 November 2021

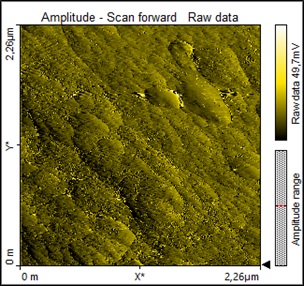

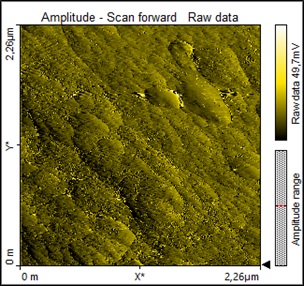

The main activity during the second research period was developing increased energy absorption syntactic foam structures. Poly(butylene adipate terephthalate) (PBAT) and polybutylene succinate (PBS) were added to two different polylactic acids with different D-lactide contents, and the resulting blends were foamed with thermally expandable microspheres (EMS). From the impact testing of these blends, we found the addition of PBAT can effectively increase the energy absorption of the inherently brittle PLA, and also that 50–50% blends are the best, as the co-continuous phase synergistically increases the mechanical properties of biopolymers.

We also continued the dynamic mechanical characterization of the traditional polymer foams to develop a new material model that accurately predicts the material response of such materials. We combined the Ogden–Hill compressible hyperelastic model with the Rayleigh damping method to represent the viscoelastic behavior of cross-linked polyethylene foams at a high strain rate. The accuracy of the simulations was validated with falling weight impact tests.

With the newly purchased Triax impact tester device, we started to test the shock-absorbing capability of polymer foams of different densities, thicknesses, cellular structures, and matrix materials. We found that with increasing drop height, the HIC value increases according to a quadratic formula.

Finally, we performed preliminary experiments to determine the cushioning curves of conventional ethylene vinyl acetate foams with a density range of 60–140 kg/m3, for which a large number of impact tests were performed with increasing impact energy. We found that the relationship between the maximum reaction force and the static load can be well approximated with an exponential curve, from which we later aim to determine a generalizable cushion curve equation that is dependent on material properties, e.g., density.

Atomic force microscope image of the co-continuous system

Section 3

1 December 2021 - 30 November 2022

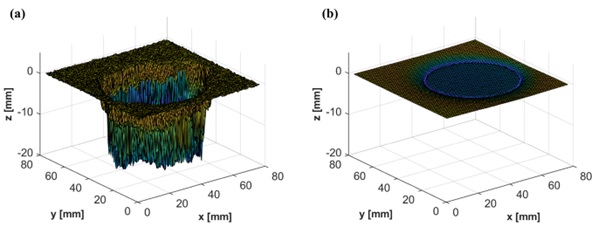

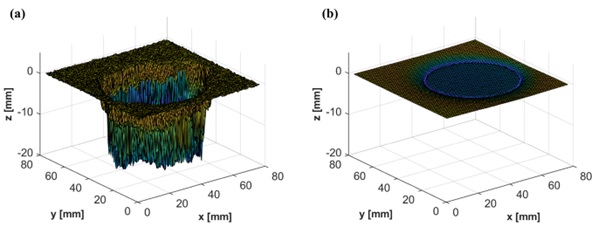

In the third research period, our main objective was to determine the cushioning curves of foamed polymer packaging materials using a novel approach. In our experiments, we performed drop-weight tests of cross-linked polyethylene and ethylene-vinyl acetate foams of different densities at different heights. Our results showed that the relationship between maximum force and static load can be described by a generalized exponential relationship. Then, we analyzed the effect of foam density and drop height on the constants in the equation and found that they depend mainly on the cell structure of the foam.

We also investigated the limitations of the applicability of a prediction method for estimating the cushioning curves in order to simplify the measurement process. The comparison of the calculated and measured data showed that the method was accurate only for lower static loads and that the limit of its applicability depends on the foam density. Based on 3D images of the tested foam samples, it was demonstrated that increasing static loads and increasing drop heights cause permanent deformation in the cell structure, which cannot be taken into account by the prediction method.

By combining the generalized equation we have defined with the prediction method, the curves can be determined with high accuracy without drop-weight tests in the static load range where no irreversible deformation occurs. This can significantly reduce laboratory time and simplify the measurement process for determining curves. Our results provide valuable information on the behavior of foam packaging materials under impact loading and may contribute to developing more efficient packaging solutions. Our combined approach offers a practical solution to simplify the determination of cushioning curves while providing accurate results.

3D scanned image of (a) 30 kg/m3 density XPE and (b) 150 kg/m3 density EVA foams samples showing the magnitude of irreversible deformation after impact testing

Section 4

1 December 2022 - 30 November 2023

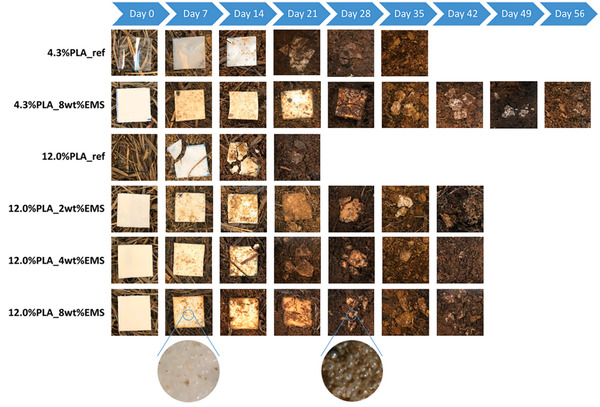

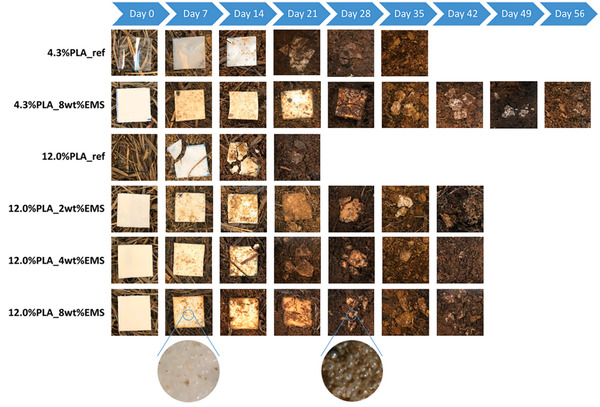

In the fourth project phase, our main goal was to investigate the compostability and recycling potential of developed biopolymer foams, driven by environmental regulations promoting biopolymers and their waste management. We examined how the D-lactide content of poly(lactic acid) and the type and dosage of expandable microsphere foaming agents affected compostability. Results showed that foam sheets with higher D-lactide content decomposed faster (49 days) compared to those with lower content (63 days) when 8 wt% foaming agent was used, due to the water diffusion properties of amorphous PLA. In poly(lactic acid)-based syntactic foams, expandable microspheres reduced the degradation rate because not only matrix hydration should take place, but other mechanism like the hydration of the expandable microsphere and the polymer matrix interface as well. However, medium-density foams still degraded within 70 days.

In addition to the compostability tests, we also investigated the end-of-life recycling potential of the produced biopolymer-based foam systems, which differed in the content and type of foaming agent. With MFI and TGA tests, we demonstrated that the PLA-based biopolymer foams underwent molecular degradation during the recycling process, leading to increased melt flow rates and reduced thermal stability, and the addition of PBAT and PBS to the mixture further increased these effects. Furthermore, we investigated the effect of the recycling process on the mechanical properties by manufacturing injection molded specimens from the regranulates. We carried out impact tests, the results of which showed that the decrease in impact strength due to recycling can be compensated by increasing the amount of blowing agent in the system.

In summary, biopolymer-based foams are recyclable with minimal property degradation, although biopolymer blends may show notable inhomogeneity in properties.

Decomposition of sheet samples as a function of composting time (the number at the beginning of each sample designation indicates its d-lactide content)

Project-related publications

Litauszki K.,

Petrény R., Haramia Zs.,

Mészáros L.: Combined effects of plasticizers and D-lactide content on the mechanical and morphological behavior of polylactic acid. Heliyon,

9, e14674/1-e14674/9 (2023)

10.1016/j.heliyon.2023.e14674 IF=3.4 Q1

Litauszki K.,

Gere D.,

Czigány T.,

Kmetty Á.: Environmentally friendly packaging foams: Investigation of the compostability of poly(lactic acid)-based syntactic foams. Sustainable Materials and Technologies,

35, e00527/1-e00527/8 (2023)

10.1016/j.susmat.2022.e00527 IF=8.6 Q1

Tomin M., Lengyel M. Á.,

Párizs R. D.,

Kmetty Á.: Measuring and mathematical modeling of cushion curves for polymeric foams. Polymer Testing,

117, 107837/1-107837/9 (2023)

10.1016/j.polymertesting.2022.107837 IF=5 D1

Tomin M.,

Török D., Pászthy T.,

Kmetty Á.: Deformation analysis in impact testing of functionally graded foams by the image processing of high-speed camera recordings. Polymer Testing,

122, 108014/1-108014/12 (2023)

10.1016/j.polymertesting.2023.108014 IF=5 D1

Tomin M., Kossa A., Berezvai Sz.,

Kmetty Á.: Investigating the impact behavior of wrestling mats via finite element simulation and falling weight impact tests. Polymer Testing,

108, 107521/1-107521/10 (2022)

10.1016/j.polymertesting.2022.107521 IF=5.1 D1

Litauszki K.,

Kmetty Á.: Tejsav oligomerrel lágyított, politejsav-alapú biopolimer habok előállítása. Acta Materialia Transylvanica,

4, 32-37 (2021)

10.33923/amt-2021-01-06 Bocz K.,

Ronkay F.,

Molnár B., Vadas D., Gyürkés M.,

Gere D.,

Marosi Gy.,

Czigány T.: Recycled PET foaming: supercritical carbon dioxide assisted extrusion with real-time quality monitoring. Advanced Industrial and Engineering Polymer Research,

4, 178-186 (2021)

10.1016/j.aiepr.2021.03.002Béky Cs., Tomin M., Kmetty Á.: Termoplasztikus elasztomerek és habosításuk- áttekintés. Polimerek, 7, 27-32 (2021)

Litauszki K.,

Kmetty Á.: Investigation of the damping properties of polylactic acid-based syntactic foam structures. Polymer Testing,

103, 107347 (2021)

10.1016/j.polymertesting.2021.107347 IF=4.931 D1

Morlin B.,

Litauszki K.,

Petrény R.,

Kmetty Á.,

Mészáros L.: Characterization of polylactic acid-based nanocomposite foams with supercritical CO2. Measurement,

178, 109385/1-109385/6 (2021)

10.1016/j.measurement.2021.109385 IF=5.131 Q1

Tomin M.,

Kmetty Á.: Polymer foams as advanced energy absorbing materials for sports applications—A review. Journal of Applied Polymer Science,

139, e51714/1-e51714/23 (2021)

10.1002/app.51714 IF=3.057 Q2

Peter T.,

Litauszki K.,

Kmetty Á.: Improving the heat deflection temperature of poly(lactic acid) foams by annealing. Polymer Degradation and Stability,

190, 109646 (2021)

10.1016/j.polymdegradstab.2021.109646 IF=5.204 Q1

Tomin M., Kmetty Á.: Különböző típusú sportszőnyegek csúszási ellenálló képességének vizsgálata. in 'XII. Roncsolásmentes Anyagvizsgáló Konferencia és Kiállítás és 10. Anyagvizsgálat a Gyakorlatban K. Online. 2021.03.17-19,1-10 (2021)

Litauszki K.,

Kmetty Á.: Characterization of chemically foamed poly(lactic acid). IOP Conference Series: Materials Science and Engineering,

903, 012018/1-012018/7 (2020)

10.1088/1757-899X/903/1/012018 Tomin M., Kmetty Á.: Különböző típusú birkózószőnyegek ütéscsillapítási képességének össze- hasonlítása a sportágban előforduló sportsérülések megelőzése céljából. Magyar Sporttudományi Szemle, 87, 37-38 (2020)

Tomin M.,

Kmetty Á.: Investigation of the energy absorption properties of cross-linked polyethylene foams . IOP Conference Series: Materials Science and Engineering,

903, 012059/1-012059/8 (2020)

10.1088/1757-899X/903/1/012059 Tomin M.,

Kmetty Á.: Evaluating the cell structure‐impact damping relation of cross‐linked polyethylene foams by falling weight impact tests. Journal of Applied Polymer Science,

138, e4999/1-e4999/12 (2020)

10.1002/app.49999 IF=3.125 Q2

Tomin M., Kmetty Á.: Ejtődárdás mérési konstrukció továbbfejlesztése polimer habok dinamikus mechanikai vizsgálatához. Gép, 71, 73-76 (2020)

Kmetty Á.,

Tomin M.,

Bárány T.,

Czigány T.: Static and dynamic mechanical characterization of cross-linked polyethylene foams: The effect of density. Express Polymer Letters,

14, 503–509 (2020)

10.3144/expresspolymlett.2020.40 IF=4.161 Q1

Litauszki K., Kmetty Á.: Politejsav kémiai habképzésének lehetőségei exoterm és endoterm típusú habképzőszerek alkalmazásával. Polimerek, 6, 1138-1142 (2020)

© 2014 BME Department of Polymer Engineering - Created by: Dr. Romhány Gábor