Development of outdoor fitness park elements using advanced composite materials and functional coatings

Project ID:

2019-1.1.1-PIACI-KFI-2019-00205

Supported by:

Hungarian National Research, Development and Innovation Office (NKFIH)

Term:

1 April 2020 - 31 Marc 2024

Supervisor (BME):

Dr. József Gábor Kovács

Dr. Ferenc Szabó

Dr. Ferenc Szabó

Participant researchers (BME):

Dr. József Gábor Kovács

Dr. András Suplicz

Dr. Ferenc Szabó

Dr. Ákos Pomázi

Dr. Béla Zink

Dr. András Suplicz

Dr. Ferenc Szabó

Dr. Ákos Pomázi

Dr. Béla Zink

Consortium partners (BME):

KATKER 2005 Kft. (Konzorciumvezető)

Project results

Section 1

1 April 2020 - 31 Marc 2021

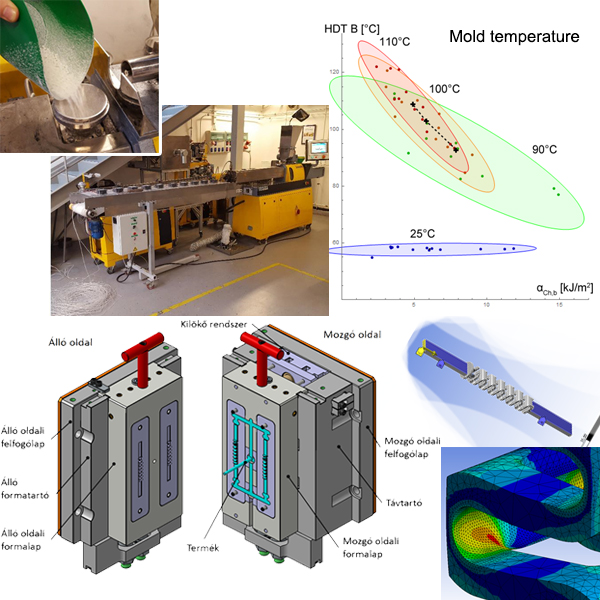

During the reporting period, we conducted a comprehensive literature search at the BME Department of Polymer Engineering to establish our knowledge in the field of polyethylene terephthalate and biopolymers. For both, we explored their main properties and their modification potentials. More extensive research has been carried out in the field of polylactic acid (PLA) as a potential raw material for our developments. The literature research has identified the main processes and additives that can modify the morphological and mechanical properties (HDT, crystallinity, modulus, impact properties) of polylactic acid according to the defined list of requirements. In our experiments, we focused on increasing the crystallinity, impact work and HDT (heat distortion temperature) of PLA. One possible method to increase the crystallinity is the use of nucleating agents (talc or Ecopromote). Still, due to the intensive cooling typically used in injection moulding, the increase achieved is not sufficient to significantly increase the HDT. Thus, in addition to the nucleation, the product must be crystallised in the mould or subsequently at elevated temperatures. This method also allows a significant increase in heat retention. Increasing the crystalline fraction increases the HDT and the impact work, and the modulus of elasticity. Furthermore, it has been shown that toughening additives alone only slightly improve the impact work of PLA, in which case a post-heat treatment at 90°C is also required. In addition to the material development, we have also prepared CAD models of two existing injection moulding tools and the products manufactured with them, which were used to build simulation models for the analysis of the injection moulding processes. We also optimized the geometry of a polymer spring for use in pens by finite element simulation for the original PP and biodegradable PLA material.

Material and product development

Section 2

1 April 2021 - 31 Marc 2022

Following the topic modification of the project, a comprehensive literature search and patent search were carried out at the Department of Polymer Engineering, using more than 160 publications. Our literature search covered engineering plastics, high-performance plastics, and fiber-reinforced composite materials that could potentially be used to develop outdoor elements. Furthermore, materials were reviewed for weather and corrosion-resistant coatings for metal and polymer elements of sports equipment. Numerical and analytical calculations have been carried out to study the stress and displacement fields in interconnecting elements currently made of PA6 GF30. This simulation method can be used to develop long-life interconnecting elements and to select their proper material.

Furthermore, the influence of different materials on the main manufacturing parameters and product quality was investigated numerically. Only polymer composite materials are expected to withstand the significant stresses in the products over long periods and under extreme weather conditions. Thus, short fiber-reinforced PA4.6 and PPS materials were developed and used to produce test specimens. These test specimens were subjected to mechanical and optical microscopy tests to assess their performance.

We have also been working on the development of epoxy- and polyurea-based surface coatings, gel coatings, and the optimization of spray application technology. These materials are developed for brushing, but with the use of a suitable solvent, these coatings can also be sprayed to form a thin, uniform layer on the surface. The coatings have been applied to carbon fiber reinforced epoxy composites and to metal surfaces that have been surface treated in various ways. It provides a good approximation of the behavior of high modulus materials also used in elements of sports equipment components. We also investigated the adhesion between the base and the coating, which is important for durabi

Section 3

1 April 2022 - 31 Marc 2023

During the reporting period, the Department of Polymer Technology at the BME continued the development of the bonding clamp, which had been started earlier. As part of this, we investigated the expected lifetime of the created composites by means of cyclic tensile tests and determined the material properties of the created composite materials for simulations. We started the redesign of the component by means of a geometric optimization algorithm, and based on the results obtained, we created and tested several design variants using finite element software. Injection moulding simulations were carried out to verify the manufacturability of the part and to identify possible weak points in the manufacturing process. We also continued to develop and test polyurea-based coatings. As part of this, the behaviour of urea coatings on polymeric surfaces was investigated and the development of a vandal-resistant punching bag was initiated. Polyurea composites reinforced with fibreglass, carbon fibre and aramid have been developed as potential materials for the outer shell of the bag. Materials made of recycled foam waste and recycled rubber were investigated as potential materials for the filling of the bag.

Section 4

1 April 2023 - 31 Marc 2024

During the work phase, we continued to develop the polymer coupling clamp. As a first step, the geometry of the clamp was finalized taking into account the given loads, using FEM software. Injection moulding simulations on the developed designs were used to investigate the resulting fibre orientation and special attention was paid to the identification of weak points due to process effects. By correcting the identified problems, an injection mouldable design was created. In preparation for the development of the mould, the applicability of several mould designs was investigated. Basic concepts for one-, two-, and four-cavity designs were prepared. To investigate the appropriate runner system design in the concepts, we also investigated several different injection locations using both cold and hot runner system. By optimising the cooling circuits of the mould concepts, we aimed to achieve the most uniform mould temperature possible, which, in addition to product quality, can also have a beneficial effect on the cycle time of the production. The work also continued to test and develop coatings, with a focus on adhesion, sprayability and hardness. We also investigated the possibility of using an additive that could provide antibacterial effects during application.

Section 5

1 April 2024 - 31 October 2024

In the work package, the pre-testing of the large series injection moulding tool was carried out. Shrinkage measurements were taken on the finished parts using non-contact 3D coordinate measuring, and the real geometry was compared with the previously designed 3D models. The assembly and static load tests of the completed parts were carried out at the Katker Ltd. site, using the straight pull and horizontal wave elements. The deformations of the clamp under load were measured at loads of 100, 200 and 300kg using non-contact 3D coordinate measurement and strain gauges. The measured values and the simulations carried out previously showed good agreement, and the results of the load test are encouraging. In this work phase, we continued the development of polyurea resins at the Department of Polymer Engineering at BME. The effect of ZnO doping with antibacterial effect, which has been used previously, was also carried out for the LPAS III system, which was found to be the most suitable for coating seating and support surfaces with lower modulus. The results of the leaching test showed similar results to those observed for SPU 30C resin. In addition to good mechanical properties, aesthetic properties are also important for a product, in which the colour accuracy and colour homogeneity of the coatings used play a role. Since the assessment and classification of colour uniformity by the naked eye requires a great deal of experience and the results can be significantly influenced by the identity of the person performing the assessment, an algorithm for measuring and classifying colour uniformity was developed in the MATLAB environment at the Department of Polymer Engineering at BME.

Project-related publications

- Horváth Sz., Kovács J. G.: Effect of processing parameters and wall thickness on the strength of injection molded products. Periodica Polytechnica-Mechanical Engineering, 68, 78-84 (2024) 10.3311/PPme.24068 IF=1.3 Q3

- Párizs R. D., Török D.: How to use prior knowledge for injection molding in industry 4.0. Results in Engineering, 23, 102667/1-102667/21 (2024) https://doi.org/10.1016/j.rineng.2024.102667 IF=6 D1

- Szuchács A., Ageyeva T., Kovács J. G.: Modeling and measuring the bonding strength of overmolded polymer parts. Polymer Testing, 125, 108133/1-108133/15 (2023) 10.1016/j.polymertesting.2023.108133 IF=5 D1

- Kotrocz L., Bakonyi P.: Investigation the temperature-dependent surface mechanical properties of PolyJet printed samples by cyclic indentation testing in a DMA system. Results in Materials, 17, 100360/1-100360/8 (2023) 10.1016/j.rinma.2022.100360

- Párizs R. D., Török D., Ageyeva T., Kovács J. G.: Multiple in-mold sensors for quality and process control in injection molding. Sensors, 23, 1735/1-1735/18 (2023) 10.3390/s23031735 IF=3.4 Q2

- Ageyeva T., Kovács J. G., Tábi T.: Comparison of the efficiency of the most effective heterogeneous nucleating agents for Poly(lactic acid). Journal of Thermal Analysis and Calorimetry, 147, 8199-8211 (2022) 10.1007/s10973-021-11145-y IF=4.4 Q1

- Zink B., Kovács J. G.: Pressure‐dependent heat transfer coefficient measurement for thermoplastic melts. Polymer Engineering and Science, 62, 1137-1146 (2022) 10.1002/pen.25912 IF=3.2 Q2

- Török D., Ageyeva T., Boros R., Kovács Á., Kovács J. G.: Developing a method for evaluating color changeover in a hot-runner multi-cavity injection mold. Polymer Testing, 115, 107759/1-107759/9 (2022) 10.1016/j.polymertesting.2022.107759 IF=5.1 D1

- Tábi T.: Talkum hatása a politejsav biopolimer tulajdonságaira. in 'XXX. Nemzetközi Gépészeti Konferencia (OGÉT 2022) Székelyudvarhely, Románia. 2022.04.21-2022.04.24.,5 (2022)

- Török D., Zink B., Ageyeva T., Hatos I., Zobač M., Fekete I., Boros R., Hargitai H., Kovács J. G.: Laser powder bed fusion and casting for an advanced hybrid prototype mold. Journal of Manufacturing Processes, 81, 748-758 (2022) 10.1016/j.jmapro.2022.07.034 IF=6.2 Q2

- Krizsma Sz. G., Suplicz A.: State-monitoring and product quality measurement of additively manufactured injection mould inserts. IOP Conference Series: Materials Science and Engineering, 1246, 012020/1-012020/8 (2022) 10.1088/1757-899X/1246/1/012020

- Semperger O. V., Suplicz A.: The effect of the titanium dioxide nanoparticles on the morphology and degradation of polyamide 6 prepared by anionic ring-opening polymerization. Polymer Engineering and Science, 62, 2079-2088 (2022) 10.1002/pen.25990 IF=3.2 Q2

- Petrovics N., Kirchkeszner Cs., Tábi T., Magyar N., Kovácsné Székely I., Szabó B. S., Nyiri Z., Eke Zs.: Effect of temperature and plasticizer content of polypropylene and polylactic acid on migration kinetics into isooctane and 95 v/v% ethanol as alternative fatty food simulants. Food Packaging and Shelf Life, 33, 100916/1-100916/10 (2022) 10.1016/j.fpsl.2022.100916 IF=8 D1

- Boros R., Ageyeva T., Golcs Á., Krafcsik O. H., Kovács J. G.: Plasma treatment to improve the adhesion between ABS and PA6 in hybrid structures produced by injection overmolding. Polymer Testing, 106, 107446/1-107446/11 (2022) 10.1016/j.polymertesting.2021.107446 IF=5.1 D1

- Tábi T., Ageyeva T., Kovács J. G.: The influence of nucleating agents, plasticizers, and molding conditions on the properties of injection molded PLA products. Materials Today Communications, 32, 103936/1-103936/8 (2022) 10.1016/j.mtcomm.2022.103936 IF=3.8 Q2

- Tábi T., Pölöskei K.: The effect of processing parameters and Calcium-stearate on the ejection process of injection molded Poly(Lactic Acid) products. Periodica Polytechnica-Mechanical Engineering, 66, 17-25 (2022) 10.3311/PPme.18246 IF=1.3

- Szuchács A., Ageyeva T., Boros R., Kovács J. G.: Bonding strength calculation in multicomponent plastic processing technologies. Materials And Manufacturing Processes, 36, 151-159 (2021) 10.1080/10426914.2021.1948052 IF=4.783 Q2

- Rajamani P. K., Ageyeva T., Kovács J. G.: Personalized mass production by hybridization of additive manufacturing and injection molding. Polymers, 13, 309/1-309/19 (2021) 10.3390/polym13020309 IF=4.967 Q1

- Csézi G., Tábi T.: Orientált biopolimer szerkezetek vizsgálata. in 'XXIX. Nemzetközi Gépészeti Konferencia (OGÉT 2021) Románia. 2021.04.23.,101-105 (2021)

- Tábi T.: Tények és tévhitek a biopolimerekkel kapcsolatban - I. rész (másodközlés). Polimerek, 7, 298-301 (2021)

- Krizsma Sz. G., Kovács N. K., Kovács J. G., Suplicz A.: In-situ monitoring of deformation in rapid prototyped injection molds. Additive Manufacturing, 42, 102001/1-102001/8 (2021) 10.1016/j.addma.2021.102001 IF=11.632 D1

- Tábi T., Ageyeva T., Kovács J. G.: Improving the ductility and heat deflection temperature of injection molded Poly(lactic acid) products: A comprehensive review. Polymer Testing, 101, 107282/1-107282/36 (2021) 10.1016/j.polymertesting.2021.107282 IF=4.931 D1

- Tábi T.: Tények és tévhitek a biopolimerekkel kapcsolatban - II. rész (másodközlés). Polimerek, 7, 337-340 (2021)

- Szabó F., Suplicz A., Kovács J. G.: Development of injection molding simulation algorithms that take into account segregation. Powder Technology, 389, 368-375 (2021) 10.1016/j.powtec.2021.05.053 IF=5.64 Q1

- Semperger O. V., Pomlényi P., Suplicz A.: Felület-bevonatolási eljárás T-RTM technológiához. Polimerek, 7, 186-192 (2021)

- Krizsma Sz. G., Suplicz A.: Additív gyártástechnológiával előállított fröccsöntő szerszámbetétek üzem közbeni deformációinak vizsgálata. Polimerek, 7, 155-160 (2021)

- Kirchkeszner Cs., Petrovics N., Tábi T., Magyar N., Kovács J., Szabó B. S., Nyiri Z., Eke Zs.: Swelling as a promoter of migration of plastic additives in the interaction of fatty food simulants with polylactic acid- and polypropylene-based plastics. Food Control, 132, 108354/1-108354/12 (2021) 10.1016/j.foodcont.2021.108354 IF=6.652 Q1

- Tábi T.: Fröccsöntött politejsav biopolimer sorozatgyárthatóságának elemzése. in 'XXIX. Nemzetközi Gépészeti Konferencia (OGÉT 2021) Románia. 2021.04.23.,200-203 (2021)

© 2014 BME Department of Polymer Engineering - Created by: Dr. Romhány Gábor