Developing a new generation of manufacturing process of tailor-made medical implants and tailor-made medical aids for additive technologies

Dr. Takács János

Dr. Kolos Molnár

Dr. Gábor Romhány

Dr. András Suplicz

Dr. Péter Bakonyi

Dr. Gábor Szebényi

Project summary

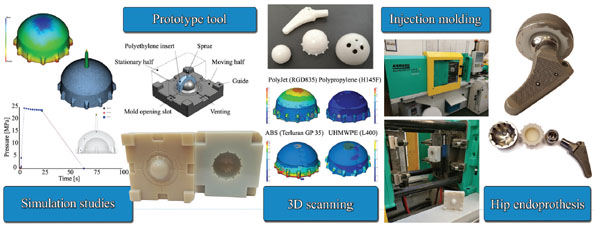

The goal of the project is to create and develop a new generation of tailor-made medical devices (which need to be tailor-made) by developing the complex system of additive manufacturing processes (data collection and processing, modelling, virtual manufacturing finite element analysis, validating based on measurements, 3D printing. The results of the project will be the creation of tailor-made implants and devices in human medicine. Current mass-produced implants cannot suit everybody since people are different and this inevitably leads to imperfect solutions. Mostly focusing on laser additive technologies, we plan to make a manufacturing standard and smart plant for the manufacturing of tailor-made medical devices which integrate smaller-scale individual development results at a systemic level by creating and maintaining long-term cooperation between the industry and BME.

Project results

Project-related publications

- Kotrocz L., Bakonyi P.: Mélységérzékeny benyomódásmérés hőmérsékletfüggésének vizsgálata DMA berendezésben. Anyagvizsgálók Lapja, 3, 30-34 (2021)

- Keszei K., Kovács N. K.: Investigation of Injection Moulded UHMWPE Liner Manufacturability. in '2020 IEEE 10th International Conference Nanomaterials: Applications & Properties (NAP) Sumy, Ukrajna. 2020.11.09-2020.11.13.,5 (2020)

- Zink B., Kovács N. K., Kovács J. G.: Thermal analysis based method development for novel rapid tooling applications. International Communications in Heat and Mass Transfer, 108, 104297/1-104297/9 (2019) 10.1016/j.icheatmasstransfer.2019.104297 IF=3.971 Q1

- Tari G., Szabó F., Suplicz A.: Áramlási egyenetlenségek valós idejű elemzése fröccsöntő szerszámban. Polimerek, 5, 424-428 (2019)

- Temesi T., Kiss Z.: Nem tömör szerkezetű, 3D nyomtatott orvostechnikai implantátumot modellező próbatestek vizsgálata. in 'XXVII. Nemzetközi Gépészeti Konferencia (OGÉT 2019) Nagyvárad, Románia. 2019.04.25-2019.04.28.,557-560 (2019)

- Kotrocz L., Bakonyi P.: Pontszerű terhelés vizsgálata egyedi mérőfeltéttel DMA berendezésben. in 'XXVII. Nemzetközi Gépészeti Konferencia Nagyvárad, Románia. 2019.04.25-2019.04.28.,292-295 (2019)

- Ureczki Á., Keszei K.: Prospects in innovative manufacturing technology of UHMWPE for prostheses and comparison with medical grade UHMWPE. Biomechanica Hungarica, 12, 43-51 (2019) 10.17489/biohun/2019/1/04

- Lukács N. L., Ficzere PP, Temesi T.: Gyártási paraméterektől függő rétegközi hibák vizsgálata CAD szoftverekkel. Gép, LXX. (3), 54-57 (2019)

- Suplicz A., Kovács N. K.: Polimer alapú 3D nyomtatott prototípus fröccsöntő szerszámbetétek formaüregének indirekt nyomásmérése. in 'OGÉT 2018: XXVI. Nemzetközi Gépészeti Konferencia: 26th International Conference on Mechanical Engin Marosvásárhely, Románia. 2018.04.26-2018.04.29.,434-437 (2018)

- Kotrocz L., Bakonyi P.: Pinpoint Loading Examinations of Poly(lactic acid) Biopolymers. Acta Technica Jaurinensis, 11, 206-217 (2018) 10.14513/actatechjaur.v11.n4.480

- Kotrocz L., Bakonyi P.: The Examination of Photopolymer-based 3D Printed Products in the Case of Pinpoint Loading. in 'iCAT2018 7th International Conference on Additive Technologies Maribor, Szlovénia. 2018.10.10-2018.10.11.,5 (2018)

- Kotrocz L., Bakonyi P.: Pontszerű terhelésre alkalmas mérőfeltét tervezése DMA berendezéshez. in 'OGÉT 2018, XXVI. Nemzetközi Gépészeti Konferencia Marosvásárhely, Románia. 2018.04.26-2018.04.29,5 (2018)

- Szebényi G., Czigány T., Magyar B., Karger-Kocsis J.: 3D printing-assisted interphase engineering of polymer composites: Concept and feasibility. Express Polymer Letters, 11, 525-530 (2017) 10.3144/expresspolymlett.2017.50 IF=3.064 Q1