National Laboratory of Cooperative Technologies

Dr. Bálint Morlin

Bertalan Papp

Péter Sántha

Bence Szederkényi

Gergő Zsolt Marton

Péter Csvila

Dr. Norbert Krisztián Kovács

Autóipari Próbapálya Zala Korlátolt Felelősségű Társaság

CollMot Robotikai kutató-fejlesztő Korlátolt Felelősségű Társaság

Femtonics Kutató és Fejlesztő Korlátolt Felelősségű Társaság

HM Elektronikai, Logisztikai és Vagyonkezelő Zártkörűen Működő Részvénytársaság

Magyar Agrár- és Élettudományi Egyetem

Magyar Honvédség Haderőmodernizációs és Transzformációs Parancsnokság

MouldTech Systems Korlátolt Felelősségű Társaság

Nemzeti Közszolgálati Egyetem

Pécsi Tudományegyetem

Számítástechnikai és Automatizálási Kutatóintézet

Széchenyi István Egyetem

Szegedi Tudományegyetem

Project summary

The National Laboratory for Cooperative Technologies builds and develops multi-purpose industrial innovation capacities and competences. Its main objective is the physical and material realisation of an "innovation space" that plays a key role in the digitalisation, research and development of industry and its related multipurpose industries at national and regional level. Domestic multi-purpose innovation developments aim at building a multi-purpose innovation system (ecosystem) based on domestic research and knowledge base, producing dual-use (military and civil) products, which, due to its need for decisive technical competences and knowledge, relies heavily on the existing and further developed competences and capacities of domestic universities and research institutions, involving innovative industrial partners. The National Laboratory for Cooperative Technologies is a programme and instrument for the development of an infrastructural and professional base for the intellectual, innovative and coordinative tasks of multi-purpose development.

Project results

Project-related publications

- Marton G. Zs., Szebényi G.: Influencing the damage process and failure behaviour of polymer composites - A short review. Express Polymer Letters, 19, 140-160 (2025) 10.3144/expresspolymlett.2025.11 IF=2.7 Q2

- Szederkényi B., Kovács N. K., Czigány T.: A comprehensive review of fiber-reinforced topology optimization for advanced polymer composites produced by automated manufacturing. Advanced Industrial and Engineering Polymer Research, 8, 113-131 (2025) 10.1016/j.aiepr.2024.05.002 IF=9.9 D1

- Szederkényi B., Kovács N.K., Czigány T.: Improving energy absorption in cellular 3D-Printed fiber–reinforced structures with radially reinforced composite shells. Composites Part B: Engineering, 301, 112513/1-112513/11 (2025) 10.1016/j.compositesb.2025.112513 IF=12.7 D1

- Suwarta P., Wisnom M. R., Fotouhi M., Wu X., Czél G.: Pseudo-ductile compressive behaviour of unidirectional thin-ply carbon /glass fibre-epoxy hybrid composites. Composites Part A: Applied Science and Manufacturing, 195, 108877/1-108877/15 (2025) 10.1016/j.compositesa.2025.108877 IF=8.1 Q1

- Marton G. Zs., Balogh F., Szebényi G.: Acoustic emission analysis and signal classification for damage modes in UD carbon/epoxy composites. Express Polymer Letters, 19, 809-821 (2025) 10.3144/expresspolymlett.2025.62 IF=2.7 Q2

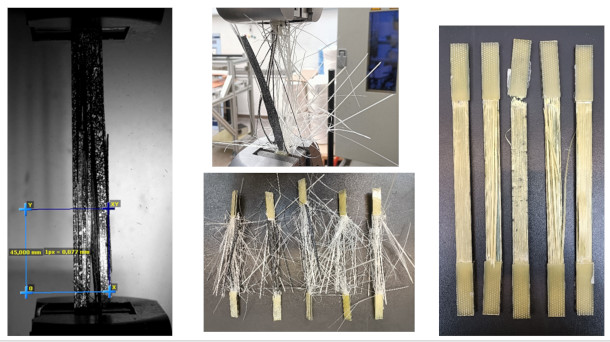

- Marton G. Zs., Szebényi G.: The effect of pattern width on the properties and behavior of interfacially engineered composites with designed failure. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország. 2024.07.02-2024.07.05.,1438-1443 (2024)

- Csvila P., Czigány T.: Multifunctional energy storage polymer composites: The role of nanoparticles in the performance of structural supercapacitors. Express Polymer Letters, 18, 1023-1038 (2024) 10.3144/expresspolymlett.2024.78 IF=2.7 Q2

- Szebényi G., Marton G. Zs., Romhány G.: Damage localization in designed failure composites. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország. 2024.07.02-2024.07.05.,156-160 (2024)

- Szederkényi B., Czigány T., Kovács N. K.: Investigation of continuous fiber–reinforced triply periodic minimal surfaces (TPMS) for high-performance energy absorption applications. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország. 2024.06.02-2024.06.05.,1651-1658 (2024)

- Szederkényi B., Rácz I., Kovács N.K., Czigány T.: Finite element modelling of continuous fiber–reinforced composites produced by automated manufacturing. IOP Conference Series: Materials Science and Engineering, 1313, 012002/1-012002/8 (2024) 10.1088/1757-899X/1313/1/012002

- Tóth Cs., Virág Á. D., Vas L. M., Kovács N. K.: Prediction and analysis of flexural stiffness for 3D-printed continuous fiber–reinforced composites with different matrix fill ratios and layer orders. Polymer Testing, 135, 108459/1-108459/11 (2024) https://doi.org/10.1016/j.polymertesting.2024.108459 IF=5 D1

- Czél G.: Direct comparison of novel unidirectional sandwich coupon designs for accurate tensile failure strain determination of carbon fibre epoxy material. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország . 2024.07.02.-05.,Vol 4. 25-32 (2024)

- Marton G. Zs., Fendrik Á., Szebényi G.: Manufacturing of composites with designed failure. IOP Conference Series: Materials Science and Engineering, 1313, 012014/1-012014/9 (2024) 10.1088/1757-899X/1313/1/012014

- Tóth Cs., Lukács N. L., Kovács N. K.: The role of the fiber–matrix interface in the tensile properties of short fiber–reinforced 3D-printed polylactic acid composites. Polymer Composites, 45, 13589-13602 (2024) https://doi.org/10.1002/pc.28720 IF=4.8 Q1

- Nemes-Károly I., Szebényi G.: Reliable methods for classification, characterization, and design of cellular structures for patient-specific implants. Materials, 16, 4146/1-4146/16 (2023) 10.3390/ma16114146 IF=3.1 Q1

- Csvila P., Czigány T.: Szén-alapú vezetőképes szerkezeti kompozitok gyártása és tulajdonságainak elemzése. Gép, 74, 39-44 (2023)

- Marton G. Zs., Mezey Z., Czél G.: Prepregből autoklávban gyártott kompozit lemezek rétegközi tulajdonságainak alakulása a térhálósítás során alkalmazott technológiai paraméterek függvényében. in 'XXXI. Nemzetközi Gépészeti Konferencia (OGÉT 2023) Temesvár, Románia. 2023.04.27-2023.04.30.,354-359 (2023)