Development of a stiff winged drone based on innovative and novel design and creation of required competences

Dr. Zoltán Tamás Mezey

Balázs Magyar

Viktor Hliva

Dr. Brúnó György Vermes

Project summary

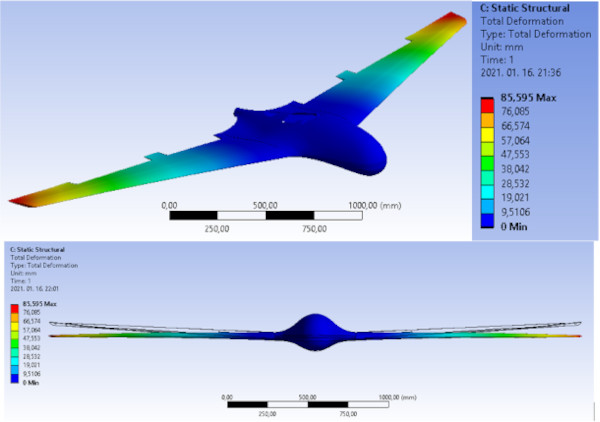

Within the framework of the project, the consortium created by Mold Tech Kft. and BME will create a multi-purpose rigid wing drone based on innovative and novel solutions and the competencies necessary for the development . Mold Tech Kft. Has practical practical experience, a competitive technical development team, which has subtractive machining methods, additive manufacturing technologies and experience in topological optimization in several ways. In 2014, the company was recognized with the Deloitte Automotive Award. The other member of the consortium (BME) can ensure the level of research essential for the success of the project by building on the flight, structure knowledge and materials science competencies required for the development of drones. The consortium has state-of-the-art 3D printing, composite and metal processing technology, and the necessary aeronautical, flow and measurement technology knowledge for successful project implementation. The project will also include research on novel composite materials and their associated special layer and shell structures. Within this, a particularly important research area will be the effect of composite inerts on the structural stability of the rigid base structure, as well as the study of boundary load conditions, vibration effects and delamination. During the further flow analysis of the wing structure, we create at the final one, the optimal design, with which the development of a unique rigid wing drone that satisfies significant market needs.

Project results

Project-related publications

- Marton G. Zs., Fendrik Á., Szebényi G.: Manufacturing of composites with designed failure. IOP Conference Series: Materials Science and Engineering, 1313, 012014/1-012014/9 (2024) 10.1088/1757-899X/1313/1/012014

- Vermes B., Czigány T.: Improving the extension–twist coupling performance of practically warpage-free laminates via layup hybridization. Journal of Reinforced Plastics and Composites, 42, 131-139 (2023) 10.1177/07316844221102941 IF=2.3 Q3

- Marton G. Zs., Mezey Z., Czél G.: Prepregből autoklávban gyártott kompozit lemezek rétegközi tulajdonságainak alakulása a térhálósítás során alkalmazott technológiai paraméterek függvényében. in 'XXXI. Nemzetközi Gépészeti Konferencia (OGÉT 2023) Temesvár, Románia. 2023.04.27-2023.04.30.,354-359 (2023)

- Hliva V., Szebényi G.: Non-destructive evaluation and damage determination of fiber-reinforced composites by digital image correlation. Journal of Nondestructive Evaluation, 42, 43/1-43/15 (2023) 10.1007/s10921-023-00957-7 IF=2.6 Q2

- Marton G. Zs., Mezey Z.: A technológiai paraméterek hatása a prepreg szerkezetek tulajdonságaira. in 'XXX. Nemzetközi Gépészeti Konferencia (OGÉT 2022) Székelyudvarhely, Románia. 2022.04.21-2022.04.24.,182-186 (2022)