Developing a novel “Green” (with a smaller ecological footprint) sports mat for recreational purposes

Project ID:

2019-1.1.1-PIACI-KFI-2019-00288

Supported by:

Hungarian National Research, Development and Innovation Office (NKFIH)

Term:

1 Marc 2020 - 29 February 2024

Supervisor (BME):

Dr. Ákos Kmetty

Participant researchers (BME):

Dr. Ákos Kmetty

Dr. Tamás Bárány

Dr. Márton Tomin

Dr. Gábor Romhány

Andrea Zelenainé Kohári

Dr. Péter Tamás-Bényei

Dr. Katalin Litauszki

Consortium partners (BME):

Polifoam Kft. (konzorciumvezető)

Project summary

Nowadays the market of polymer foams is growing globally. The total weight of polymer foam products manufactured in the USA

exceeds three million tons, which are used by industries such as the packaging industry, the automotive industry, the construction

industry and the sports industry. The most important characteristic of foamed polymer products is outstanding energy absorption.

Sports mats are used in many sports either for safety or as a surface for sports activity. Energy absorption mats are used for example

in indoor rock climbing gyms, for martial arts, gymnastics, pole vaulting, and also as protective mats for ski slopes. It is important to

note that these foam products are mostly made from petroleum-based polymers ; these polymers and the manufacturing

technologies have a considerable ecological footprint. The most commonly used materials are poly(vinyl chloride) (PVC),

polyurethane (PUR), polyethylene (PE) and poly(vinyl chloride)-acrylonitrile butadiene rubber (PVC-NBR). Nowadays most

manufacturers in the sport and leisure segment make PVC-based mats, mostly because of their low price and their high surface

durability. PVC-NBR-based materials are a new family of materials which combine the advantageous properties of PVC with the

flexibility of NBR and therefore comfortable products can be made from them. The use of PVC, however, requires extreme care due to

the chlorine in its chemical structure and the plasticizer necessary during its processing. The plasticizer content of PVC can migrate to

the surface of the PVC product in long-term use, and this causes a serious environmental and health risk issues due to the phthalates.

Due to its chemical structure, much attention must be paid to the handling of PVC products at the end of their lifetime, as

hydrochloric acid is produced when PVC is burnt. When it gets into contact with water, it produces an acidic mixture, which can cause

acid rain. Nowadays PVC waste is usually used to produce energy, which technically means burning; this energy is a tiny fraction of

the energy necessary to produce and process PVC; handling costs are high and the ecological footprint is large. The goal of our

project is to develop flexible, elastomer-based foam structures for sports purposes with a small ecological footprint and with less or

even no PVC. We also intend to develop the related manufacturing technology with special emphasis on mass-production. The

product is likely to attract a great deal of attention and it is estimated that a considerable volume will be sold both on the domestic

and the international market. In the fast-paced and stressful lifestyle of the 21st century, there is an increasing need for recreational

and health-preserving activities. Numerous studies have proved that yoga and similar activities promote a happier and more

balanced life. The development team includes several of BME’s researchers who have many years of related professional experience,

and Polifoam Kft has 35 years of foam-making experience. This expertise and experience guarantee success and efficiency.

Project results

Section 1

1 Marc 2020 - 28 February 2021

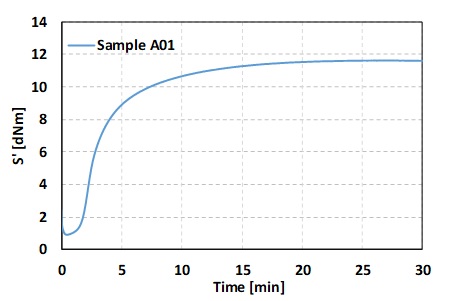

Competitive product analysis was carried out during the first section of the project. The approximate composition of the products was determined with analytical tests. Based on mechanical tests, we determined the requirements for the product to be developed. We determined the requirements for quality and comfort and the properties of the reference samples. In addition, we did an extensive literature search. In the literature search, the range of the most common polymer-rubber raw materials, their properties, and the available formulations was also explored. Market research was also carried out, during which we purchased the competing products, examined them and graded them based on the criteria we developed. During this section, we also set the main research directions by collecting materials and their combinations available to develop a PVC-free product. We performed extensive laboratory tests and developed experimental designs. We started the development of PVC-free foam materials according to the experimental design. The impact assessment of the components used in the recipes, and the vulcanization and foamability experiments of the mixtures were performed according to the project schedule. The documentation generated during this work section includes the results for the competing products; an in-depth and detailed characterization of the reference material, the properties to be achieved and their target values. Therefore, we produced a profile of properties characteristic of high-quality sports mattresses and the production technology parameters required for the production of NBR-PVC based foams used as a reference in later foam development. The production technology parameters have been determined at laboratory scale and semi-industrial scale.

Vulcanization curve of sample A01

Section 2

1 Marc 2021 - 28 February 2022

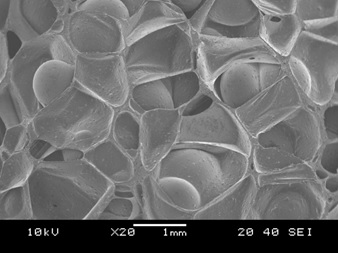

During the second milestone of the project, we examined and analyzed PVC-free formulations in detail and selected the most promising ones. Subsequently, the reference formulations for reduced-PVC and PVC-free formulations were also checked. Using the raw materials and excipients selected on the basis of the preliminary studies, we developed a basic recipe for each alternative material group. Following continuous evaluation of the results, modifications were made to the formulation of the PVC-free blends on a laboratory scale to produce small amounts of blends. The processability of the blends on the purchased rubber extruder was investigated. After the processability tests, the most promising formulations were selected and the laboratory and factory samples made from them were analyzed. We will determine further development directions. We examined the laboratory and factory samples, based on the results of which we performed recipe optimization steps, and a literature review was carried out on several raleted topics.

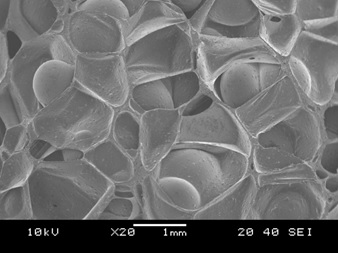

Figure 1 Scanning electron micrograph of a PVC-free foam structure

Section 3

1 Marc 2022 - 28 February 2023

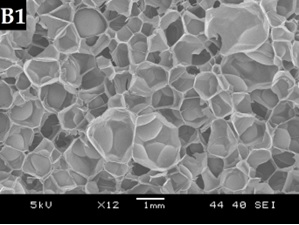

During the third milestone, within the framework of the project, we thoroughly examined and further developed PVC-free formulations based on the results achieved in the previous work phase, aiming to better meet the needs of athletes. To accomplish this, we conducted laboratory-scale tests in small quantities to assess the properties and processability of the mixtures, varying the quantities of different components. Building upon the developed PVC-free base formulation, our goal was to develop formulations associated with biopolymers, preceded by comprehensive literature research. We examined several different biopolymers and selected the most promising one for further development. Under laboratory conditions, we optimized the formulation, processing, and foaming technologies, followed by comprehensive investigations (mechanical, morphological, etc.) on the most successful foams. To further enhance the user experience, we delved deep into the convertibility possibilities of foams intended for various sports applications. This involved an initial literature review, followed by extensive and successful experiments. Through these experiments, we established correlations between the properties of the final foams and the parameters applied during the experiments.

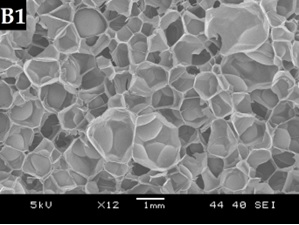

Scanning electron micrograph of a biopolymer-associated foam structure

Section 4

1 Marc 2023 - 29 February 2024

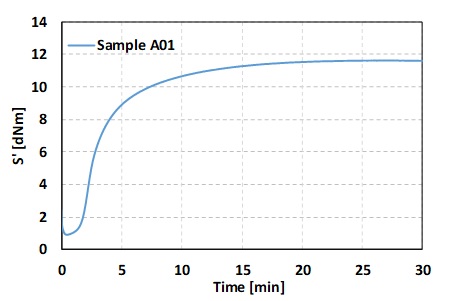

In the framework of the project, during the fourth milestone, we thoroughly examined and analyzed the formulations containing biopolymers developed as a result of the previous work milestone. Subsequently, we selected the most promising ones. Following this, we conducted further mixing trials and developed a technology that can be scaled up to industrial size equipment. Then, we comprehensively examined the properties of the foams manufactured on an industrial scale. Further developments were carried out in the area of alternative rubbers, and the prepared foams were thoroughly examined (mechanics, morphology, etc.). We also conducted a comprehensive analysis of the storage time of raw mixtures produced under industrial conditions (vulcanization, curing, foamability), which is crucial from a manufacturing perspective. We also assessed the conversion possibilities of the foams containing biopolymers we developed and conducted investigations in this regard. Furthermore, we examined the industrial samples, primarily in terms of vulcanization properties and reproducibility. Mapping the relationship between the composition of the formulations, vulcanization characteristics, behavior during foaming, and the properties of the mattresses produced during the experiments contributed to facilitating future research tasks on the one hand, and on the other hand, it provided an opportunity to develop a diverse product portfolio that meets customer needs, including biopolymer mixtures, in comparison with the experience of Polifoam manufacturers.

Vulcanization curves during the storage time experiments

Project-related publications

Béky Cs., Tomin M., Kmetty Á.: Termoplasztikus elasztomerek és habosításuk- áttekintés. Polimerek, 7, 27-32 (2021)

© 2014 BME Department of Polymer Engineering - Created by: Dr. Romhány Gábor