Development of ductile polimer composites with designable interfacial adhesion

Dr. Péter Tamás-Bényei

Balázs Magyar

Viktor Hliva

Project summary

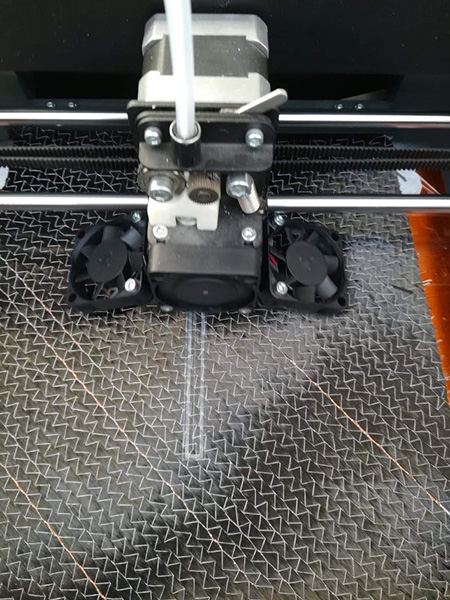

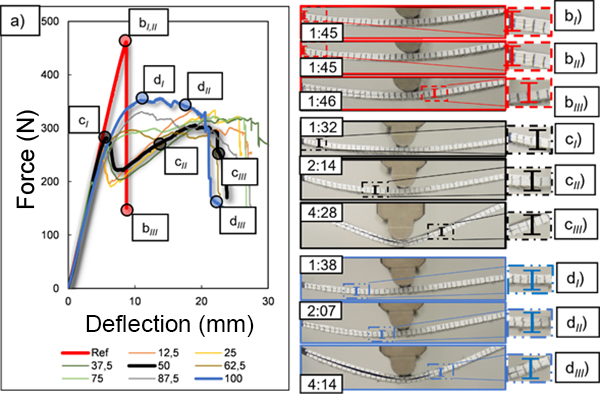

The main research hypothesis is if the modification of the interlaminar adhesion in long fiber reinforced thermoset matrix composites can improve their ductility. Through the research process, many important questions about the role of adhesion in multiphase systems will be addressed and answered: What is the optimal level of adhesion providing ductile behavior through the relative slippage of the constituents without compromising the strength provided by good load transfer? How do interlaminar patterns effect the global and local deformation of a composite structure? Is there a difference in the behavior in composites with regular and random interlaminar patterns? How does pattern geometry (spacing, fiber diameter, periodicity, orientation) effect the global and local mechanical characteristics? Can a thermoplastic interphase material act as a healing agent in a composite system?

Project results

Project-related publications

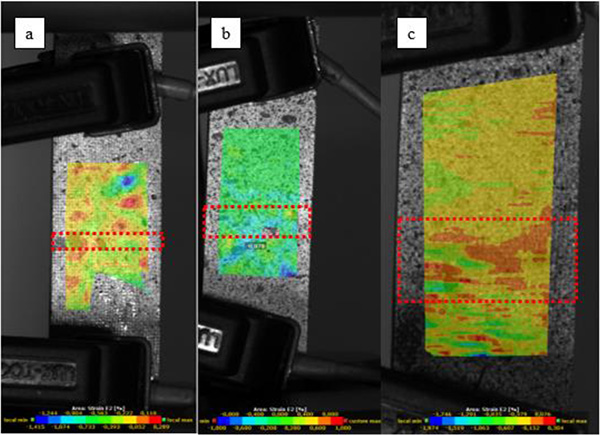

- Hliva V., Szebényi G.: Non-destructive evaluation and damage determination of fiber-reinforced composites by digital image correlation. Journal of Nondestructive Evaluation, 42, 43/1-43/15 (2023) 10.1007/s10921-023-00957-7 IF=2.6 Q2

- Tamás-Bényei P., Sántha P.: Potential applications of basalt fibre composites in thermal shielding. Journal of Thermal Analysis and Calorimetry, 147, 1-9 (2023) 10.1007/s10973-022-11799-2 IF=3 Q2

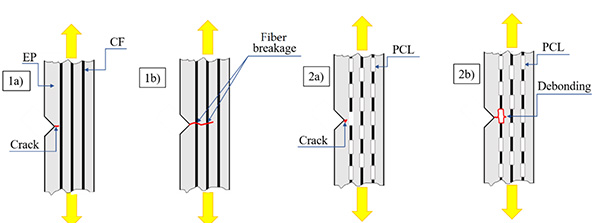

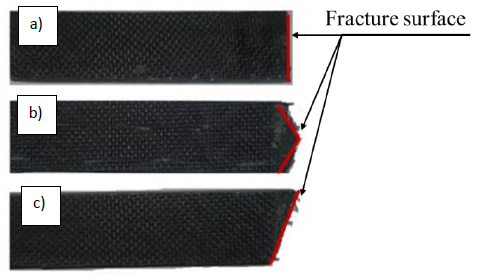

- Szebényi G., Magyar B., Czigány T.: Achieving pseudo-ductile behavior of carbon fiber reinforced polymer composites via interfacial engineering. Advanced Engineering Materials, 23, 2000822/1-2000822/7 (2021) 10.1002/adem.202000822 IF=4.122 Q2

- Szebényi G., Magyar B., Czigány T.: Achieving pseudo-ductile behavior of carbon fiber reinforced polymer composites via interfacial engineering. Advanced Engineering Materials, 23, 2000822/1-2000822/7 (2021) 10.1002/adem.202000822 IF=4.122 Q2

- Karadi D. T., Sipos A. A., Halász M., Hliva V., Hegyi D.: An elastic phenomenological material law of technical textile with a nonlinear shear behaviour. Journal of Reinforced Plastics and Composites, 40, 759-769 (2021) 10.1177/07316844211005842 IF=3.383 Q2

- Magyar B., Czigány T., Szebényi G.: Metal-alike polymer composites: The effect of inter-layer content on the pseudo-ductile behaviour of carbon fibre/epoxy resin materials. Composites Science and Technology, 215, 109002/1-109002/8 (2021) 10.1016/j.compscitech.2021.109002 IF=9.879 Q1

- Szebényi G., Hliva V., Magyar B.: Development of interphase engineering techniques for the ductility improvement in CF/EP composites - Comparison of NDT methods for delamination localization. Materials Today: Proceedings, 34, 113-116 (2020) 10.1016/j.matpr.2020.01.403

- Szebényi G., Blößl Y., Hegedűs G., Tábi T., Czigány T., Schledjewski R.: Fatigue monitoring of flax fibre reinforced epoxy composites using integrated fibre-optical FBG sensors. Composites Science and Technology, 199, 108317/1-108317/8 (2020) 10.1016/j.compscitech.2020.108317 IF=8.528 D1

- Hliva V., Szebényi G.: Mesterséges rétegelválás modellezése polimer kompozitokban. in 'XXVII. Nemzetközi Gépészeti Konferencia (OGÉT2019) Nagyvárad, Románia. 2019.04.25-2019.04.28.,197-200 (2019)

- Szebényi G., Hliva V.: Detection of Delamination in Polymer Composites by Digital Image Correlation—Experimental Test. Polymers, 11, 523/1-523/11 (2019) 10.3390/polym11030523 IF=3.426 Q1

- Szebényi G., Hliva V., Tamás-Bényei P.: Investigation of delaminated composites by DIC and AE methods. in 'International Conference on Composite Materials (ICCM22) Melbourne, Australia. 2019.08.11-2019.08.16,7 (2019)

- Magyar B., Szebényi G., Czigány T.: Comparison of different interfacial engineering methods to achieve pseudo-ductile behaviour of carbon fibre reinforced polymer composites. in 'International Conference on Composite Materials (ICCM22) Melbourne, Australia. 2019.08.11-2019.08.16,9 (2019)

- Tamás-Bényei P., Bitay E., Kishi H., Matsuda S., Czigány T.: Toughening of Epoxy Resin: The Effect of Water Jet Milling on Worn Tire Rubber Particles. Polymers, 11, 529/1-529/11 (2019) 10.3390/polym11030529 IF=3.426 Q1

- Szebényi G., Magyar B.: Effect of fibre sizing on the interlaminar properties of polyamide matrix composites. IOP Conference Series: Materials Science and Engineering, 426, 012044/1-012044/7 (2018) 10.1088/1757-899X/426/1/012044