Development of recyclable-by-design high performance fibre reinforced polymer composites

Dr. Ákos Pomázi

Prof. Dr. Andrea Toldy

Project summary

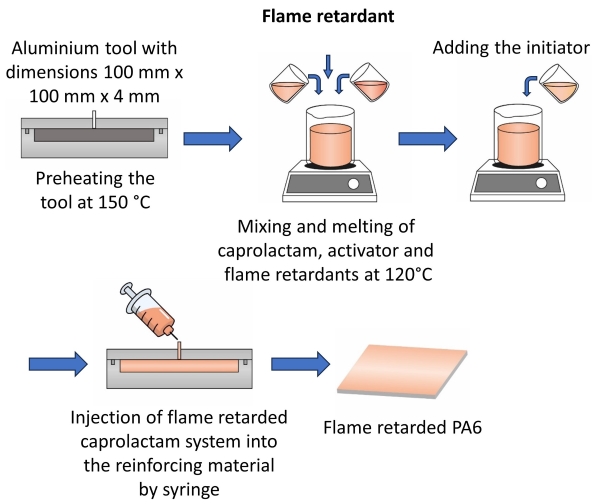

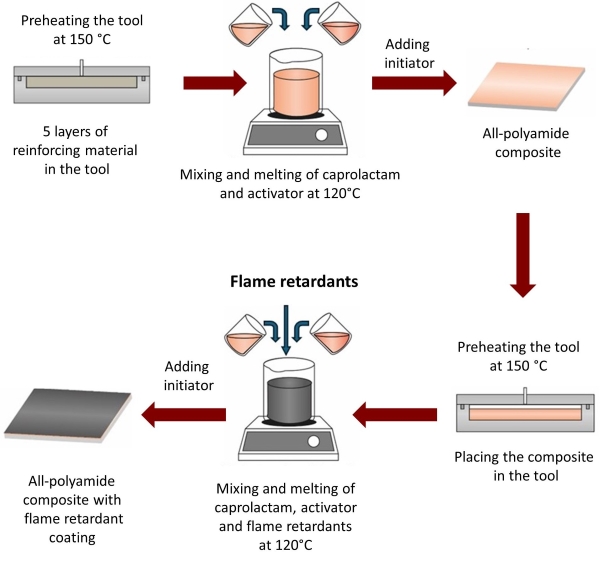

At present, there are no technologies available for the large-scale material recycling of fibre reinforced thermoset composites. Therefore, this proposal focuses on the development of recyclable-by-design high performance fibre reinforced polymer composites. In particular, two main development directions are envisaged: development of high performance vitrimer based recyclable and repairable carbon fibre reinforced composites and development of high performance flame retarded all-polyamide composite by thermoplastic resin moulding. As for the first direction, the aim is to develop novel vitrimer-based, recyclable and repairable thermoset polymers with tunable topology freezing transition temperature, suitable for high-temperature composite applications, and to elaborate an industrially feasible recycling method that provide recycled matrices and fibre in the same or similar quality to the benchmark composite materials. Furthermore, deeper understanding of structure-property relationships, recycling and repairing mechanisms of vitrimers is foreseen. Concerning the second direction, the aim is to develop self-reinforced, recyclable, in situ polymerised polyamide 6 composites and enable their used in high temperature application areas by flame retardant coatings appropriate for productive and reproducible in-mould coating. The proposal aims to accomplish not only the recycling of the composites but also the reuse of the obtained components, their characterisation including the effect of repeatedly recycled flame retardant additives on the fire performance of composites made from recycled materials.

Project results

Project-related publications

- Toldy A.: Safe and sustainable-by-design: Redefining polymer engineering for a greener future.

- Sántha P., Tamás-Bényei P., Toldy A.: From scrap to structure: The challenges of carbon fibre recycling.

- Kovács Zs., Toldy A.: Synergistic flame retardant coatings for carbon fibre-reinforced E-caprolactam-based polyamide 6 composites: fire performance and mechanical properties. Polymer Degradation and Stability, 240, 111495/1-111495/14 (2025) https://doi.org/10.1016/j.polymdegradstab.2025.111495 IF=6.3 D1

- Toldy Andrea, Poór Dániel István, Szolnoki Beáta, Geier Norbert, Pomázi Ákos: Synergistic flame retardancy of carbon fibre-reinforced polyimine vitrimer composites via vitrimer-based intumescent coating. Composites Part A: Applied Science and Manufacturing, 198, 109135/1-109135/13 (2025) 10.1016/j.compositesa.2025.109135 IF=8.1 Q1

- Kovács Zs., Toldy A.: Flame retardancy via in-mould coating and durability of flame retardants after mechanical recycling in all-polyamide composites prepared by in situ polymerisation. Macromolecular Materials and Engineering, 310, 202400325/1-202400325/12 (2024) 10.1002/mame.202400325 IF=4.2 Q2

- Toldy A., Poór D. I., Szolnoki B., Devecser B., Geier N., Pomázi Á.: Comparative study of flame retardancy in polyimine vitrimers and composites: Evaluating additive and reactive flame retardants acting via gas-, solid-, and combined-phase mechanisms. Journal of Materials Science & Technology, 196, 101-111 (2024) 10.1016/j.jmst.2024.01.047 IF=11.2 D1

- Pomázi Á., Poór D. I., Geier N., Toldy A.: Optimising recycling processes for polyimine-based vitrimer carbon fibre-reinforced composites: A comparative study on reinforcement recovery and material properties. Materials, 17, 2372/1-2372/15 (2024) 10.3390/ma17102372 IF=3.1 Q1

- Poór D. I., Tobey M., Taynton P., Pomázi Á., Toldy A., Geier N.: A comparative machinability analysis of polyimine vitrimer, epoxy and polycarbonate polymers through orthogonal machining experiments. International Journal of Advanced Manufacturing Technology, 131, 1361-1376 (2024) 10.1007/s00170-024-13087-9 IF=2.9 Q2

- Kovács Zs., Toldy A.: Development of flame retardant coatings containing hexaphenoxycyclotriphosphazene and expandable graphite for carbon fibre-reinforced polyamide 6 composites. Polymer Degradation and Stability, 230, 111017 (2024) 10.1016/j.polymdegradstab.2024.111017 IF=6.3 D1

- Kovács Zs., Toldy A.: Synergistic flame retardant coatings for carbon fibre-reinforced polyamide 6 composites based on expandable graphite, red phosphorus, and magnesium oxide. Polymer Degradation and Stability, 222, 110696/1-110696/11 (2024) 10.1016/j.polymdegradstab.2024.110696 IF=6.3 D1

- Kovács Zs., Toldy A.: Flame retardant coatings for E-caprolactam-based self-reinforced polyamide 6 composites. in 'ECCM21 – 21st European Conference on Composite Materials Nantes, Franciaország. 2024.07.02.-05.,989-995 (2024)

- Gere D., Pomázi F., Szöllősi A., Jahanpeyma P., Ermilov A. A., Baranya S., Toldy A.: Mikroműanyag szennyezés vizsgálata a Duna budapesti szakaszán. Polimerek, 2, 66-72 (2024)

- Kovács Zs., Pomázi Á., Hollósi E., Toldy A.: ε-kaprolaktám alapú égésgátló bevonat fejlesztése szénszál erősítésű poliamid 6 kompozitokhoz. Polimerek, 3, 90-96 (2023)

- Zielinski D., Szpecht A., Pomázi Á., Kovács Zs., Szolnoki B., Pinke B., Toldy A., Smiglak M.: Multifunctional modifying systems based on ionic liquids for epoxy resin systems and composites. Applied Sciences-Basel, 13, 10661/1-10661/14 (2023) 10.3390/app131910661 IF=2.5 Q1

- Kovács Zs., Pomázi Á., Toldy A.: Development of multifunctional flame-retardant gel coatings for automotive applications. Coatings, 13, 345/1-345/14 (2023) 10.3390/coatings13020345 IF=2.9 Q2